In today’s fast-paced business world, understanding the key differences between takt time, cycle time, and lead time is crucial to optimizing production processes and improving customer satisfaction. While these terms are often used interchangeably, they refer to different aspects of the production process. This post will explore the key differences between takt time, cycle time, and lead time and their impact on production processes.

Takt Time

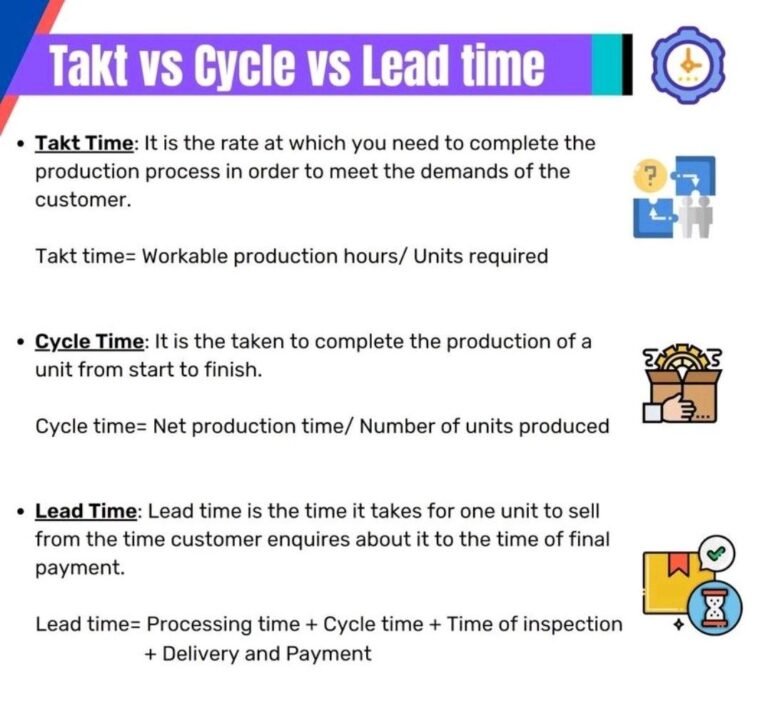

Takt time is a concept used in lean manufacturing, which refers to the pace of production needed to meet customer demand. It is calculated by dividing the available production time by the customer demand. Takt time ensures that production is aligned with customer demand and that there is no overproduction or underproduction.

The primary purpose of takt time is to ensure the production process is balanced and synchronized. This means that each process in the production line works simultaneously to avoid bottlenecks and overproduction. Takt time helps organizations identify the ideal cycle time to meet customer demand and improve production efficiency.

Cycle Time

Cycle time is the time it takes to complete a process from start to finish. It is time it takes to complete one cycle of a process, including all the steps involved in that process. Cycle time is used to measure a single process’s efficiency and identify improvement areas.

The primary purpose of cycle time is to identify areas where the production process can be improved to reduce the time taken to complete a process. By reducing cycle time, organizations can improve their production efficiency, reduce costs, and improve customer satisfaction. Cycle time can also help organizations to identify bottlenecks in the production process, which can be addressed to improve efficiency.

Lead Time

Lead time is the time it takes to complete a process from start to finish, including all the waiting time between processes. It includes all the time spent on each process, including processing, waiting, and transportation time. Lead time is a critical factor in measuring the efficiency of the production process and ensuring customer satisfaction.

The primary purpose of lead time is to identify areas where the production process can be improved to reduce the time taken to complete a process. By reducing lead time, organizations can improve their production efficiency, reduce costs, and improve customer satisfaction. Lead time can also help organizations to identify bottlenecks in the production process, which can be addressed to improve efficiency.

Key Differences between Takt Time, Cycle Time, and Lead Time

Takt time, cycle time, and lead time are closely related concepts that are often confused. The key differences between these concepts are:

- Purpose: The primary purpose of takt time is to synchronize production processes with customer demand. The primary purpose of cycle time is to measure the time taken to complete a single process and identify areas for improvement. The primary purpose of lead time is to measure the time taken to complete a process, including all the waiting time between processes, and identify areas for improvement.

- Calculation: Takt time is calculated by dividing the available production time by customer demand. Cycle time is calculated by measuring the time to complete a single process. Lead time is calculated by measuring the time to complete a process, including all the waiting time between processes.

- Application: Takt time synchronizes production processes to meet customer demand. Cycle time is used to identify areas for improvement in the production process. Lead time measures and manages the time to complete a process, including all the waiting time between processes.

Takt, cycle, and lead time are crucial metrics that help manufacturers measure and manage their production processes. Takt time is used to synchronize production processes with customer demand, while cycle time measures the time taken to complete a single process and identify areas for improvement. Lead time is used to measure and manage the time taken to complete a process, including all the waiting time between processes, and identify areas for improvement.

Using these three concepts, manufacturers can optimize their production processes, reduce waste, and improve efficiency. Takt time helps eliminate waste and ensure that processes are balanced, while cycle time helps manufacturers identify bottlenecks and areas for improvement. Lead time, on the other hand, helps manufacturers measure and manage the time taken to complete a process, including all the waiting time between processes, and improve customer satisfaction.

Manufacturers must continuously improve their production processes in today’s highly competitive business environment. By using takt time, cycle time, and lead time, manufacturers can optimize their production processes, reduce costs, and improve customer satisfaction. Therefore, manufacturers must understand the critical differences between these concepts and how they can be used to improve their production processes.