Introduction:

This case study examines a medium-sized manufacturing company that produces automotive parts. The company has been facing challenges with high levels of waste and increased product rejections, leading to a decline in customer satisfaction and profits. To address these issues, the company decided to implement the Six Sigma methodology and leverage its tools to identify, analyze, and resolve the root causes of the problems.

Objective:

The primary objective of this case study is to demonstrate how the Six Sigma methodology and tools can help a manufacturing company reduce waste, minimize product rejections, and, ultimately, improve overall process efficiency.

Methodology:

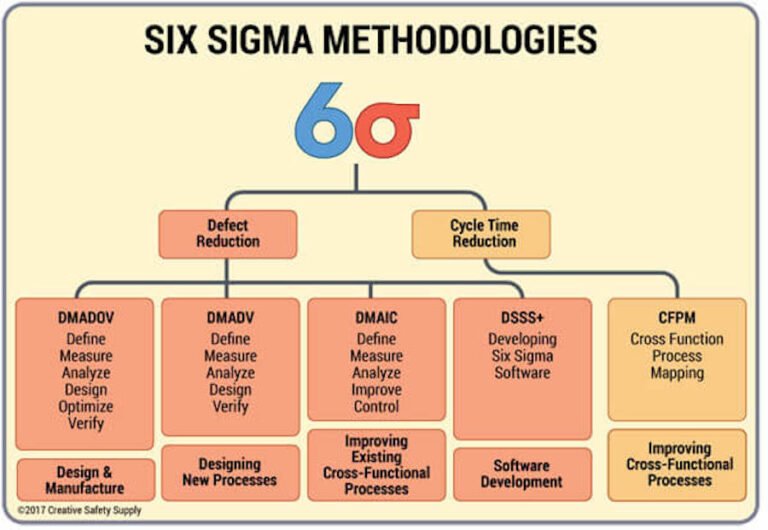

The company used the DMAIC (Define, Measure, Analyze, Improve, and Control) framework to approach the problem. The following Six Sigma tools were employed:

- Process Mapping

- Pareto Analysis

- Cause and Effect Analysis

- Control Charts

- Root Cause Analysis

- Statistical Process Control (SPC)

Results:

Define Phase: The project team defined the problem as “high levels of waste and increased product rejections,” affecting customer satisfaction and company profitability. The goal was to reduce the product rejection rate by 50% within six months.

Measure Phase: The team gathered historical data on waste generation and product rejection rates. They observed that the rejection rate had increased from 5% to 12% in the past year, significantly affecting the company’s overall performance.

Analyze Phase: The team used Pareto Analysis to identify the top causes of product rejections, which were found to be primarily due to dimensional inaccuracies, surface defects, and incorrect material usage. Cause and Effect Analysis was then employed to investigate further the underlying factors contributing to these issues.

Improve Phase: The team identified the root causes of the problems and developed action plans to address them. For example, they implemented better training for operators, improved maintenance schedules for equipment, and revised material handling procedures. Control Charts were used to monitor the improvements in real time.

Control Phase: The team established Statistical Process Control (SPC) to ensure the improvements were sustained over time. This involved setting up control charts to continuously monitor critical process parameters and implementing a system for operators to report any deviations from the established control limits.

Conclusion:

The company successfully reduced waste and minimized product rejections by applying the Six Sigma methodology and leveraging its tools. Within six months, the product rejection rate dropped by 55%, surpassing the initial goal. The improvements increased customer satisfaction, higher profits, and a more efficient manufacturing process.

This case study demonstrates the effectiveness of Six Sigma tools in identifying, analyzing, and resolving complex problems in manufacturing processes. Companies can significantly improve their efficiency, reduce costs, and enhance customer satisfaction by applying these tools.