Process Excellence

How High-Performing Teams Sustain Momentum Every Day

Productivity isn't just about effort—it's about alignment, clarity, and the right systems. Discover how Strategy Deployment, Daily Accountability, Gemba, Problem Solving, and Leader Standard Work create a high-impact, sustainable approach to performance improvement.

Read More »How to Master Gemba Walks and Spot Waste in Plain Sight

Discover the often-overlooked practice of Gemba Walks—one of the most powerful tools in Lean methodology. Learn how to observe processes with fresh eyes, spot hidden inefficiencies, and turn simple insights into lasting improvements.

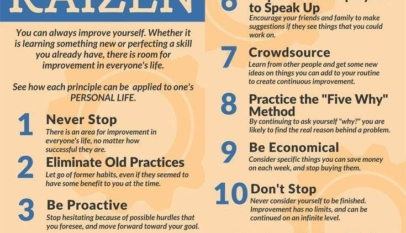

Read More »How to Transform Your Business with Kaizen Principles

Discover how the Kaizen methodology can revolutionize your business operations by eliminating inefficiencies, fostering continuous improvement, and boosting morale. This guide breaks down the step-by-step process of implementing a successful Kaizen workshop while sharing an inspiring story of transformation in unexpected circumstances.

Read More »Harnessing Business Excellence in Manufacturing Through the PDCA Approach

Explore the transformative power of the PDCA approach in driving business excellence within the manufacturing sector. Discover key performance indicators and strategies that promote a robust company culture, enhancing employee satisfaction and competitive advantage.

Read More »