Innovation vs. Kaizen Explained

Discover how Innovation and Kaizen differ in approach, speed, risk, and impact—and when to…

Read More »

OPL – One Point Lesson Template – Free Download

One Point Lesson is a tool to convey information. Designed to enhance knowledge and…

Read More »

Lean

The Lean Spectrum: How to Balance Structure and Flexibility

Striking the right balance between structure and flexibility in Lean methodology is crucial for long-term success. Over-standardization can stifle innovation, while too much flexibility leads to inefficiency and chaos. This article explores how organizations can fine-tune their approach to Lean, ensuring optimal efficiency without sacrificing adaptability.

Lean Six Sigma Study Plan

Master the essentials of Lean Six Sigma with this concise study plan. Discover powerful DMAIC strategies, practical tools, and consulting insights to enhance your career and drive measurable business improvement.

Empowering Management with Training Within Industry: A Deep Dive into Second-Line Supervisor Job Instructions

The guide outlines four key steps for initiating this process: creating a timetable for training needs, developing job breakdowns, encouraging a clean and well-arranged workplace, and following the four steps of the original job instruction card for supervisors. To maintain the use of job instructions, managers should regularly review time…

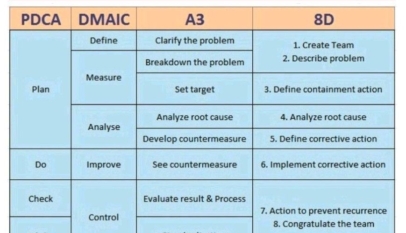

A Comparative Analysis of Popular Continuous Improvement Methodologies: PDCA, DMAIC, A3, and 8D

Explore the differences between four popular continuous improvement methodologies - PDCA, DMAIC, A3, and 8D. This blog post offers a comprehensive comparison, examining their unique steps and applications, to help you choose the most suitable approach for your organization's improvement journey.

Latest Articles

9 Powerful Habits of High-Impact Manufacturing Leaders

Discover 9 powerful habits that consistently drive transformation in high-performing manufacturing organizations. From developing…

How High-Performing Teams Sustain Momentum Every Day

Productivity isn't just about effort—it's about alignment, clarity, and the right systems. Discover how…

How to Take Google & IBM Coursera Courses for Free—And Even Get a Certificate

Want to take top-rated Coursera courses from Google and IBM—without spending anything? Discover how…

Mastering the Supplier Quality Audit: A Practical Guide

A strong supplier relationship starts with a structured audit. This guide breaks down each…

Mastering SPC: A Practical Guide to Process Stability and Capability

Statistical Process Control (SPC) isn’t just about charts and formulas—it’s the key to building…

How Great Leaders Structure Their Meetings

Discover the four types of meetings that high-performing leaders use to align teams, boost…

Why OLE Is the Missing Link in Lean

Most manufacturers measure OEE to assess machine efficiency—but what about the entire line? This…

Innovation vs. Kaizen Explained

Discover how Innovation and Kaizen differ in approach, speed, risk, and impact—and when to…