Root Cause Analysis Stacking: A Game-Changer for Problem Solving

Root Cause Analysis Stacking offers a structured method to streamline problem-solving by combining causal…

Read More »

OPL – One Point Lesson Template – Free Download

One Point Lesson is a tool to convey information. Designed to enhance knowledge and…

Read More »

Lean

Lean Six Sigma Study Plan

Master the essentials of Lean Six Sigma with this concise study plan. Discover powerful DMAIC strategies, practical tools, and consulting insights to enhance your career and drive measurable business improvement.

Empowering Management with Training Within Industry: A Deep Dive into Second-Line Supervisor Job Instructions

The guide outlines four key steps for initiating this process: creating a timetable for training needs, developing job breakdowns, encouraging a clean and well-arranged workplace, and following the four steps of the original job instruction card for supervisors. To maintain the use of job instructions, managers should regularly review time…

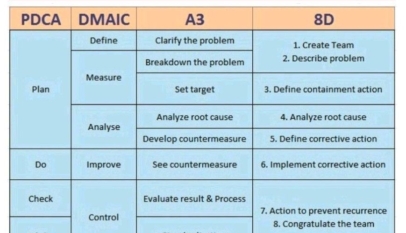

A Comparative Analysis of Popular Continuous Improvement Methodologies: PDCA, DMAIC, A3, and 8D

Explore the differences between four popular continuous improvement methodologies - PDCA, DMAIC, A3, and 8D. This blog post offers a comprehensive comparison, examining their unique steps and applications, to help you choose the most suitable approach for your organization's improvement journey.

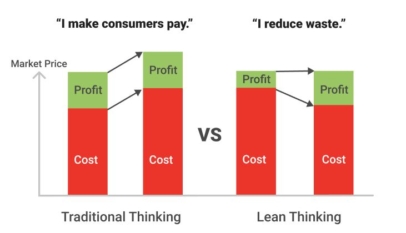

Embracing Lean Thinking: Reducing Waste Instead of Passing Costs to Consumers

Embrace lean thinking to tackle rising costs while preserving customer satisfaction. Lean management principles focus on reducing waste and improving efficiency, providing an alternative to passing costs onto consumers. Companies like Toyota, Nike, and Intel have successfully adopted lean thinking, demonstrating its benefits in cost savings, productivity, and customer loyalty.…

Latest Articles

Root Cause Analysis Stacking: A Game-Changer for Problem Solving

Root Cause Analysis Stacking offers a structured method to streamline problem-solving by combining causal…

Lean Six Sigma Study Plan

Master the essentials of Lean Six Sigma with this concise study plan. Discover powerful…

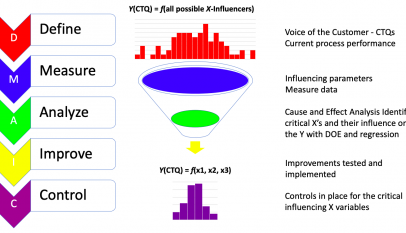

A Complete Guide to Lean Six Sigma DMAIC

Explore the DMAIC methodology, the core of Lean Six Sigma. From defining problems to…

Strategic KAIZEN: Senior Executives’ Mindset Overhaul

Ignite the spark of strategic productivity to achieve target profitability! In today’s fast-paced environment,…

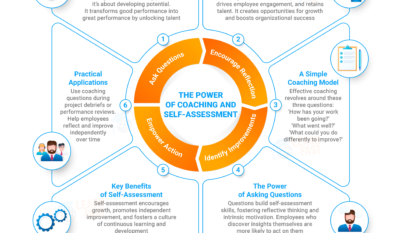

The Art of Coaching and Self-Reflection

Discover how reflective coaching and self-assessment can transform your leadership and empower your team…

The Strategic KAIZEN Transformation

1) Opening The global market has been expanding for some time now. As a…

ISO 9001: Your Roadmap to Success

Learn how to navigate the ISO 9001 Map effectively by understanding key quality system…

Building a Productive Workforce Through Improvement Plans

The Performance Improvement and Corrective Action process offers a structured framework for addressing performance…