Process Excellence

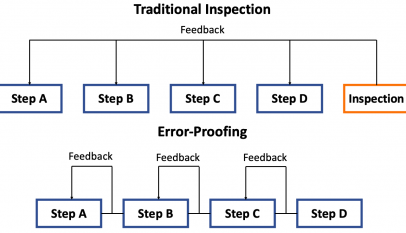

What is Error-Proofing or Poka-Yoke

A strategy of implementing “fail-safe mechanisms” to prevent a process from producing defects.A timeless common-sense concept that was more recently popularized by Japanese industrial engineer Shigeo Shingo. Error-proofing is a philosophy whereby it is unacceptable to make even a very small number of defects or mistakes, and the only way…

Read More »Project Management Tools & Techniques. Part 3

PROJECT MANAGEMENT – Step 4: CONTROL Definition of Control:Comparing progress to planned performance so that deviations can be corrected, thereby achieving project objectivesPlanning and Control as “Siamese Twins”You must plan in order to control nPlanning is done only so control can be achieved Planning and Control cannot be separated.There is…

Read More »Project Management Tools & Techniques. Part 2

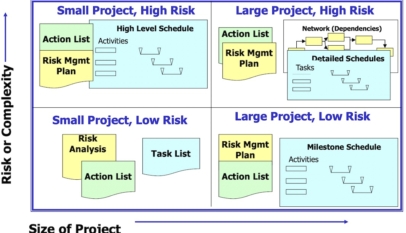

PROJECT MANAGEMENT – Step 3: PLANNING Kick-off MeetingWork Plan & ResponsibilitiesRisk Analysis (Risk Scan, Management Plan) PROJECT MANAGEMENT – Step 3: PLANNING – Kick Off Meeting OBJECTIVES: Ensure Everyone has a Full Understanding of: Project Scope Project Objectives Roles & Responsibilities Develop a Practical, Detailed Work Plan Create Ownership of…

Read More »Project Management Tools & Techniques. Part 1

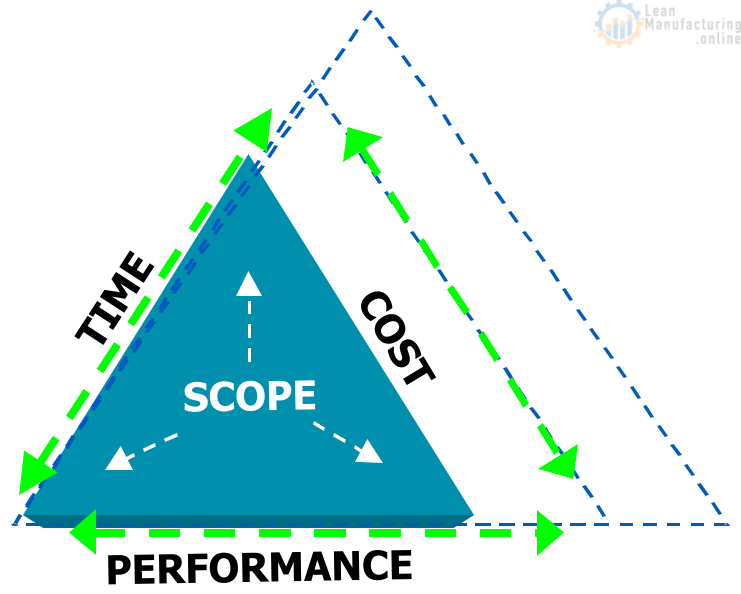

What is a Project? A PROJECT is…a sequence of Unique Complex Activities having a Specific Purposethat Must be completed by a Specific Timeusing Resourcesaccording to Agreed Performance Characteristics of Projects Inter-related TasksIn Some Way UniqueConcerned With ChangeNo Practice Or RehearsalDefined OutcomesA Definite Start and FinishInvolve People and Resources PROJECT MANAGEMENT…

Read More »