Visual Controls are very useful tools for a quick inspection to determine the condition of assembly to avoid or reduce downtime. One Point Lesson below gives examples of accessible chain and timing belt drive inspections.

Artificial Intelligence

Continuous Improvement

Lean

Lean Manufacturing

Lean Six Sigma

Productivity

Safety

TPM

World Class Manufacturing

November 19, 2025

0 629

Gemba Walk GPT: The Smartest Way to Turn Observations Into Real Improvement

November 16, 2025

0 1,329

How to Create a Step-by-Step Reveal Animation in PowerPoint

Book reviews

Continuous Improvement

Leadership and Continuous Improvement

Lean Manufacturing

Lean Six Sigma

October 4, 2025

0 2,830

Explore the Best Free Online Libraries in 2025

October 3, 2025

0 2,753

TPM Master Plan: The Roadmap to World-Class Manufacturing

October 3, 2025

0 1,110

Exploring Statistical Software: Features, Costs, and Flexibility

5S

Autonomous Maintenance

Early Equipment Management

Education and Training

Focused Improvement

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

TPM

World Class Manufacturing

January 31, 2023

0 6,599

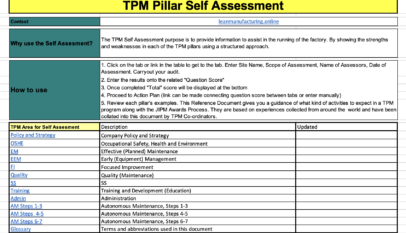

TPM Pillar Self Assessment

April 12, 2022

0 7,092

Detailed Autonomous Maintenance (AM) Master Plan. Steps 1 – 5

5S

Autonomous Maintenance

Early Equipment Management

Education and Training

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

World Class Manufacturing

March 1, 2022

0 1,911

Example of Food Manufacturing site review

Autonomous Maintenance

Focused Improvement

Planned Maintenance

Quality

Safety, Health and Environment

TPM

TPM Introduction

Training

World Class Manufacturing

February 15, 2022

0 6,712

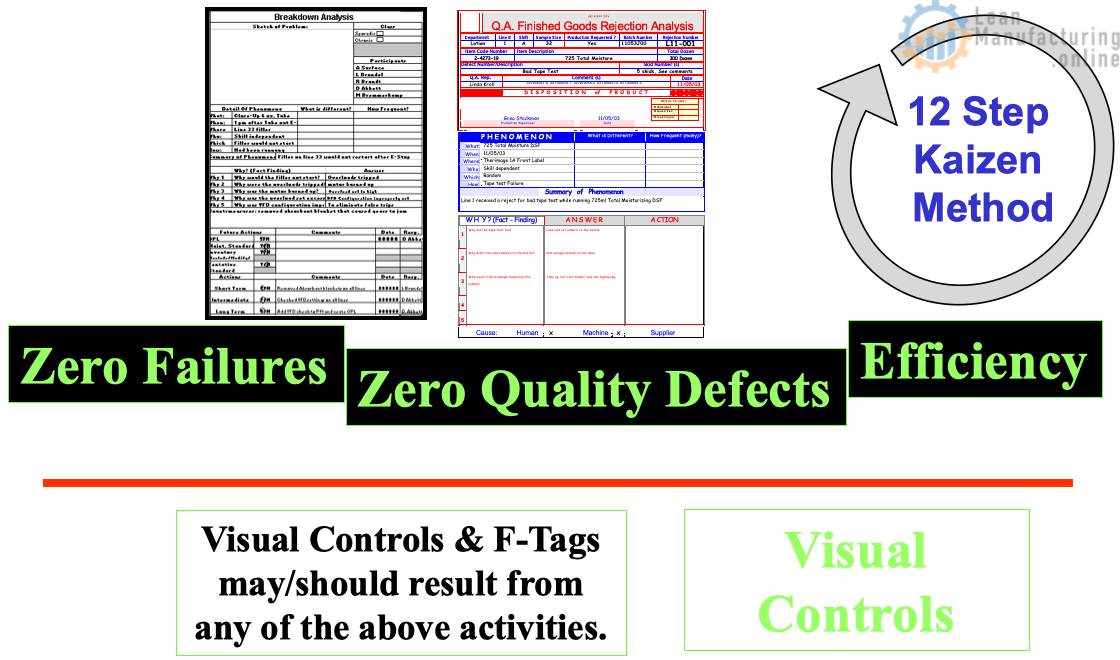

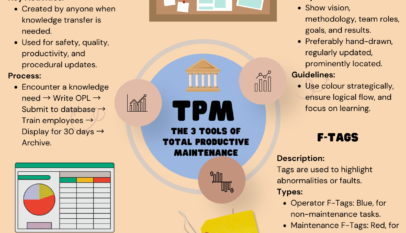

The 3 Tools of TPM

December 25, 2021

0 1,992

How to improve the support for Autonomous Maintenance (AM) teams

Most Popular

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M …