World Class Manufacturing

Team Working in TPM

Why are we interested in Team Working? Restructuring the Workplace Fewer levels of hierarchyMore demandsLess timeNo room for empty jobsNo room for empty bossesGreater need for skilled workforceTrue productivity True Productivity Means… More TeamworkMore brainsLess stupidity TPM provides : “WHAT TO DO” Team Working provides: ”THE WAY TO DO IT”…

Read More »Autonomous Maintenance Step 4 Case Study

Autonomous Maintenance Blog Education and Training Manufacturing Support Planned Maintenance Training World Class Manufacturing

Implementation Team Values: IntegrityDemand diversity of thought!Responsibility and accountabilityDefine & communicate roles, responsibilities, and actions plans for teams and individuals! 5W & 1H WHAT: Major Stoppages/BreakdownsWHEN: DailyWHERE: Packaging LinesWHO: MechanicWHICH: N/AHOW: Not Enough time to Eliminate SUMMARY OF PROBLEM:Mechanics do not have enough time to Eliminate Major Stoppages/Breakdowns that occur…

Read More »Lessons Learnt as a communication tool

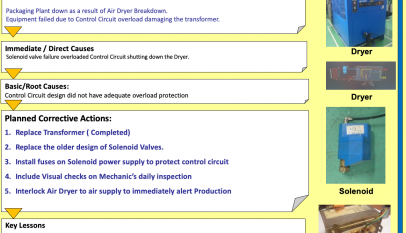

Another great tool to create short but meaningful communication is Lessons Learnt. It can be used to communicate Safety, Quality or Productivity issues to all Team Members. Goal is to explain what happened and how to avoid it from happening in the future. Lessons Learnt Principles applied are to: Take…

Read More »Broken Parts Museum – Analyzing and Preventing Breakdowns due to Forced Deterioration

5 Why Analysis Autonomous Maintenance Blog OPL Root Cause Analysis Training World Class Manufacturing

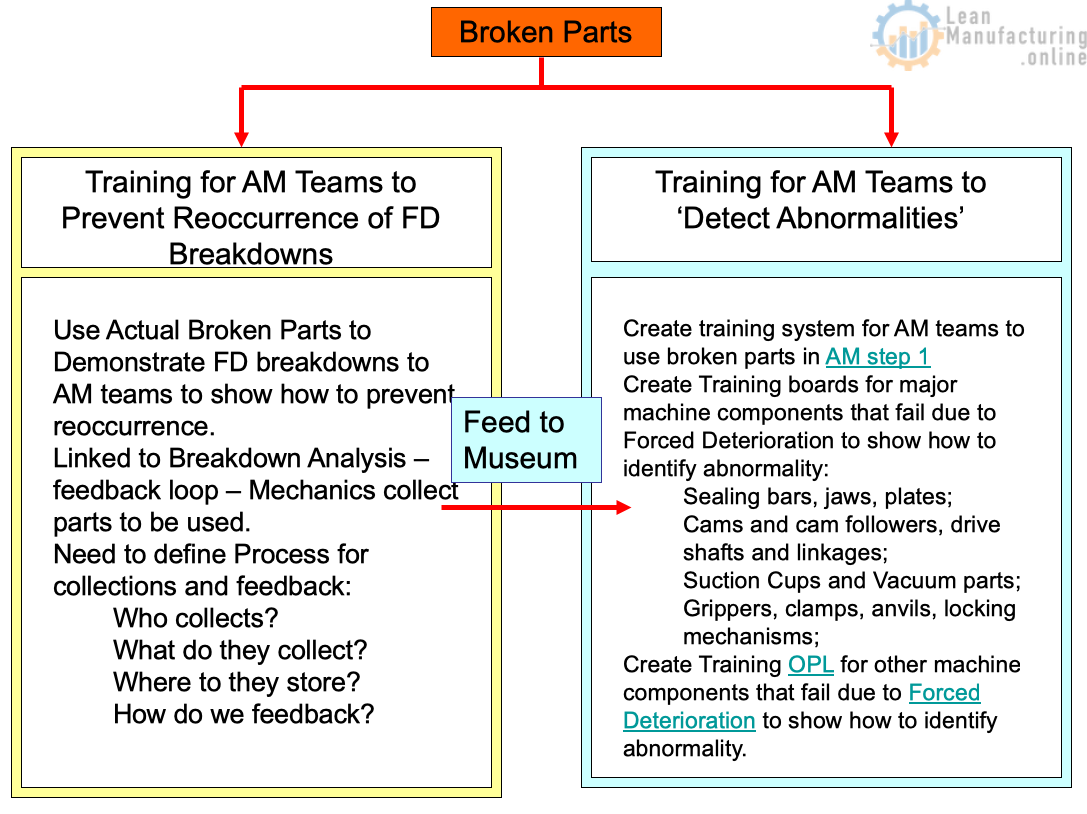

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members. Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to…

Read More »