Quality

Global Food Safety Initiative – Preparation for FSSC 22000. Part 4 ISO22000 Section 6, Resource Management

6.0 Resource Management This clause is about making sure there are enough resources to meet the needs of the FSMS in terms of: People Infrastructure Work Environment 6.2.1 General The food safety team and the other personnel carrying out activities having an impact on food safety shall be competent and shall…

Read More »Global Food Safety Initiative – Preparation for FSSC 22000. Part 3. Food Safety Management Systems Interpretation training

ISO 22000; CLAUSE 4 Food safety management system 4.1 General Requirements This clause is about documenting and maintaining an effective food safety management system, and updating it when necessary. The organization shall a) ensure that food safety hazards that may be reasonably expected to occur in relation to products within…

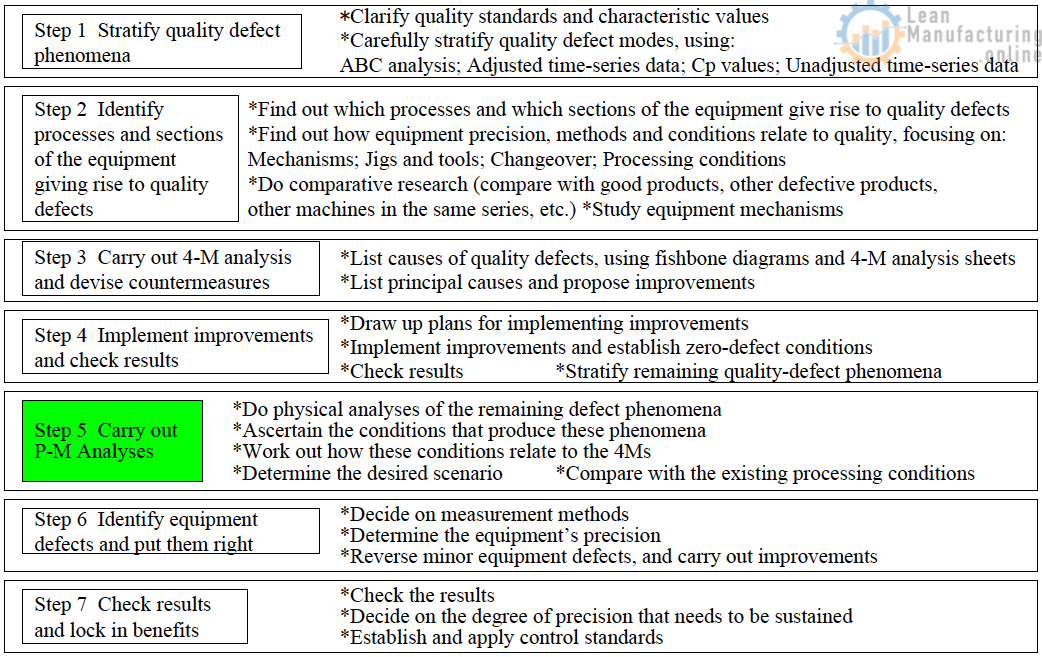

Read More »Deep KAIZEN for Quality Defects

Quality defect and rework losses are defined as: Material wasted by producing defective products that have to be scrapped; The time lost (less output) when reprocessing defective products that can be turned into good ones. Some typical examples of quality defects and rework Topping up containers outside the line when…

Read More »Global Food Safety Initiative – Preparation for FSSC 22000. Part 2. Food Safety Management Systems Interpretation training

What are Management Systems? Basic Definitions What are the objectives of a management system? What should be included in a Food Safety Management System? What are the Food Safety Critical Success factors? What are the business benefits of a Food Safety Management System? Definitions Management System – system to establish…

Read More »