Quality

Developing Quality Maintenance. 10-Step Procedure

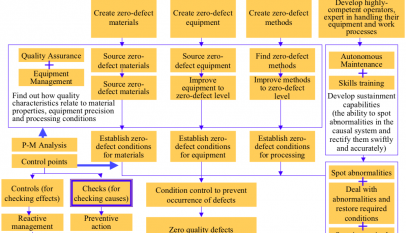

Aims of Quality Maintenance - Confirm quality characteristics (built in by process or equipment), Study and assess defects or complaints where quality characteristics are not satisfied; Investigate individual processes where defect mode has occurred

Read More »The Basic Philosophy of Quality Maintenance

The key to ensuring quality (i.e. production standards) on the shop floor is achieving optimal conditions for the 4 Ms (Men/Women, Machinery, Materials, Methods).

Read More »The 7 QC Tools

Exploring the 7 QC tools in lean manufacturing reveals a comprehensive set of strategies that enhance efficiency and minimize variability in production processes. The tools range from Cause-and-Effect diagrams, which focus on controlling processes, to Checksheets that streamline data collection, and Histograms that graphically represent data patterns. Pareto Diagrams prioritize…

Read More »The Meaning of Quality

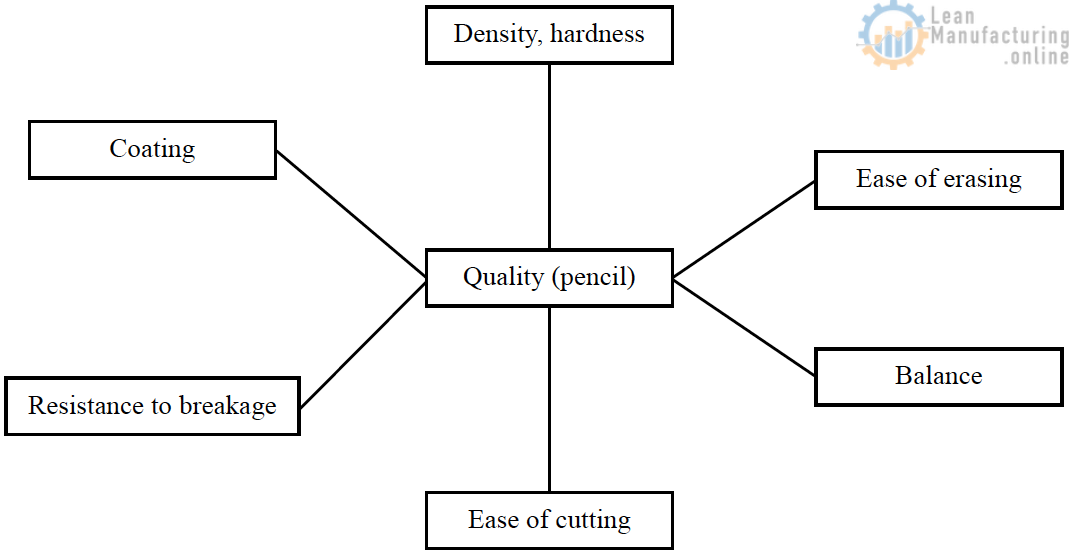

Required quality When a consumer purchases a product, she purchases not just the object itself but the effects, or functional quality, that object can provide. These effects include tangible or “true quality” such as the ability to cut things, write words and so forth. However, consumers also require non-functional quality,…

Read More »