Quality

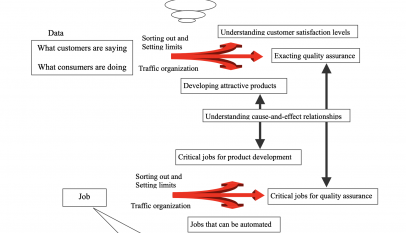

The Need for Quality Function Deployment

What kind of result and relationship does the implementation of work operations produce?

Read More »PQCDSM KPI Definitions

Safety, Health, and Environment Total Recordable Frequency Rate Total Recordable Frequency Rate for employees is the sum of all the lost time accidents (LTA), restricted work cases (RWC), and all medical treatment cases (MTC) expressed as a rate per hundred thousand hours worked. The data reported should cover only each…

Read More »Outline of Quality Function Deployment

What is quality function deployment? In describing what quality function deployment is about, we will explain from a new perspective that is not limited to the conventional idea of “utilizing the principles of analysis and integration, diversification and visualization, generalization and localization.” Quality Function Deployment, or QFD, was developed in…

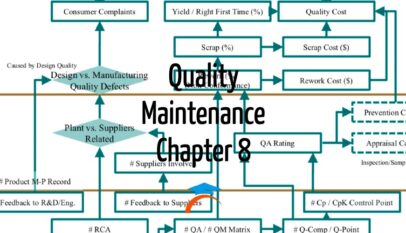

Read More »Quality Maintenance. Part 1

What is Quality Maintenance? The Basic Philosophy of Quality Maintenance The 4 Ms – the Determinants of Quality Prerequisites for Promoting Quality Maintenance Developing Quality Maintenance (A 10-Step Procedure)

Read More »