Manufacturing Support

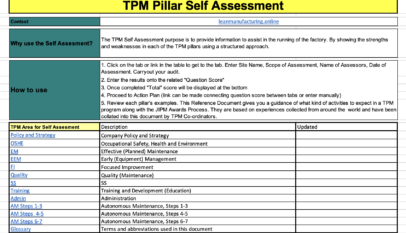

TPM Pillar Self Assessment

5S Autonomous Maintenance Early Equipment Management Education and Training Focused Improvement Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM World Class Manufacturing

The TPM Self Assessment’s purpose is to provide information to assist in running the factory. By showing the strengths and weaknesses of each TPM pillar using a structured approach.

Read More »Example of Food Manufacturing site review

5S Autonomous Maintenance Early Equipment Management Education and Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment World Class Manufacturing

Master Plan Show the results for the main objectives with consistent benchmarks and targets – Breakdowns, Minor Stops, Quality Defects and ZERO loss time accidents.Highlight why the Site needs TPM. “TPM is not the objective; it is the way to deliver the objectives.”Each pillar must have key indicators to link…

Read More »TPM 3 Levels – path to World-Class Manufacturing

5S Autonomous Maintenance Blog Change Management Early Equipment Management Early Product Management Education and Training Focused Improvement Instructor Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction World Class Manufacturing

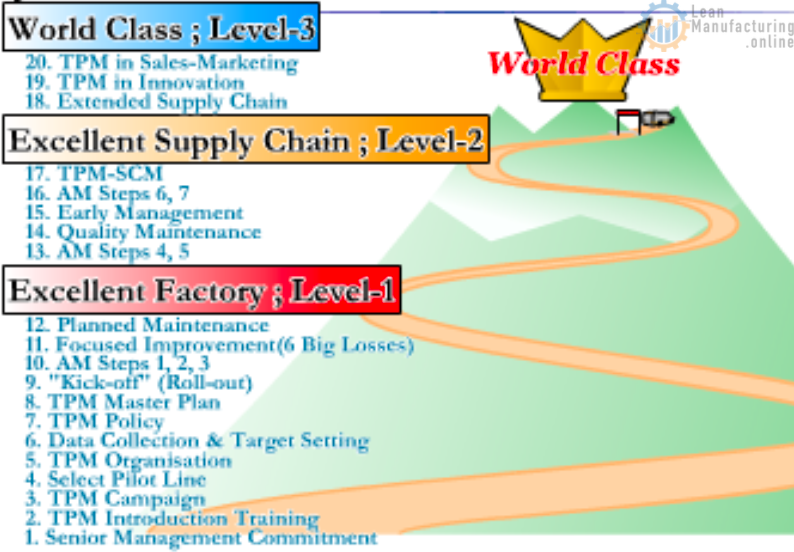

Getting to Level 3 of Total Productive Maintenance will require a LOT OF hard work, but it’s doable. Listed below is a 20-Step process on how to get there, steps 1-12 are part of Level 1 (Excellent Factory), steps 13-17 – Level 2 (Excellent Supply Chain) and finally, steps 18-20…

Read More »Strengthening of Administrative Division Functions through MAKIGAMI Analysis. Part 1

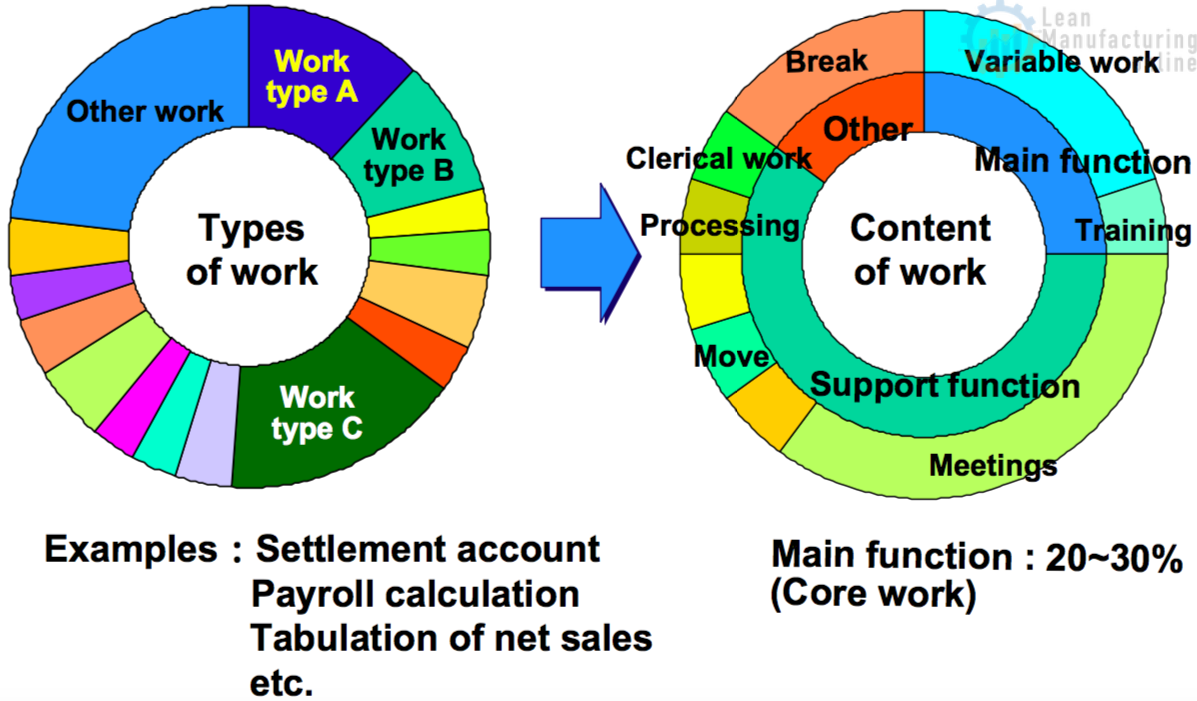

MAKIGAMI analysis achieves greater operating efficiency not merely by reducing the eight major losses in administrative work, but by contributing significantly and positively to management.

Read More »