5S

TPM Pillar Self Assessment

5S Autonomous Maintenance Early Equipment Management Education and Training Focused Improvement Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM World Class Manufacturing

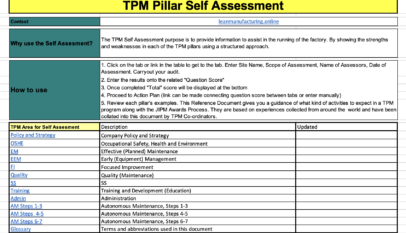

The TPM Self Assessment’s purpose is to provide information to assist in running the factory. By showing the strengths and weaknesses of each TPM pillar using a structured approach.

Read More »5S standard in the right place at the right time

In this factory, to strengthen 5S sustainability, the 5S standard was located at the right place, close to the workstation.The 5S Standard is a simple one-page combination of dot points to provide a simple explanation and a photo of “what good looks like”. After the Team has transformed the area…

Read More »How can Shadow boards improve the efficiency of your process?

Shadow boards are tools which help organize workstations, setup carts, tool cribs and practically anything that needs organizing! Let me take you through an example of how a company increased their productivity by 35% just by installing a simple shadow board. Shadow boards help find a home for every object;…

Read More »5S Audit Checklist and Report

Randomly scheduled audits for compliance are essential to sustain a 5S environment. Frequency of audit dependent on “traffic”, “risk”, demonstrated compliance (sustaining efforts, past audits), etc.

Read More »