Root Cause Analysis

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M Analysis of a system or subsystem. The goal of this 4M Analysis Procedure is to reduce losses in the factory by using the Equipment Attributes as a guideline to achieve this end. Focused Improvement training can be…

Read More »Bearing failures – Root Cause Analysis and countermeasures

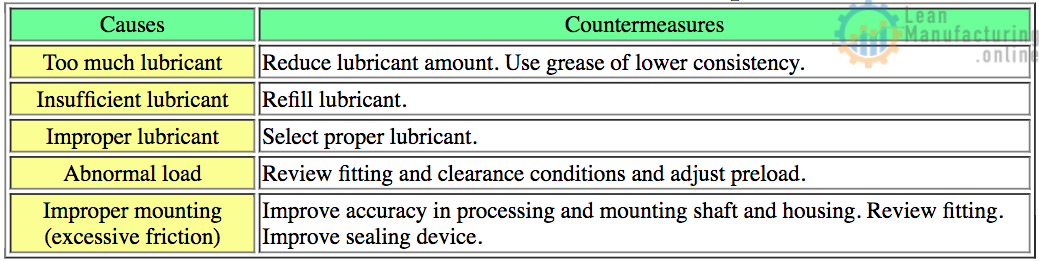

When a bearing is used under ideal conditions, it will only be damaged by rolling fatigue. Damage due to rolling fatigue may occur very early, however. If damage is found on a bearing, it is important to examine the phenomenon properly and identify the causes, even if the damage is…

Read More »DMAIC

DMAIC is a widely used problem-solving methodology for Define, Measure, Analyze, Improve, and Control. This methodology is commonly applied in Six Sigma projects and is designed to provide a structured approach to identifying and eliminating process defects. Each phase of the DMAIC process involves specific activities and tools that help…

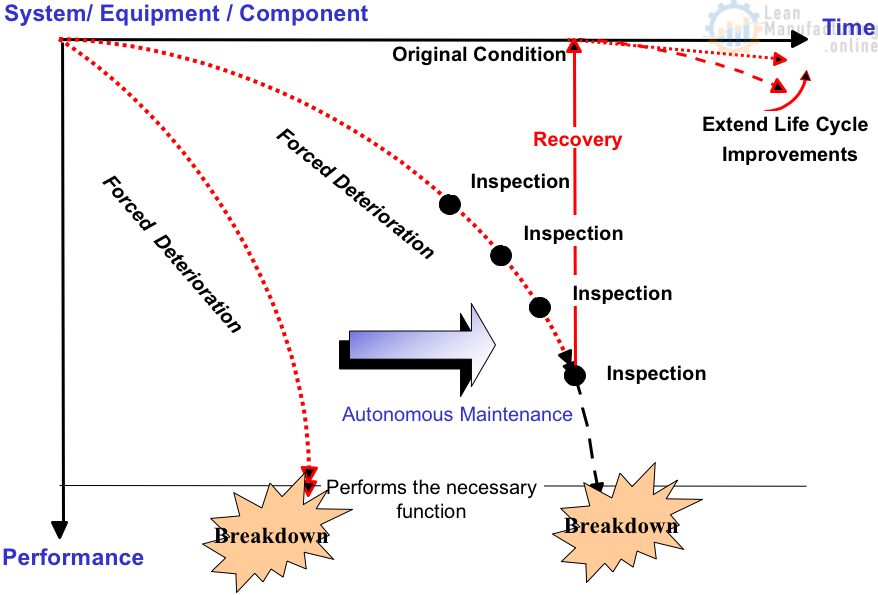

Read More »Approaching Zero Breakdowns by advancing Breakdown analysis

What is Maintenance? Maintenance: It is a set of developed, organized and administered activities with the aim to economically viable ensure the operational status of a specific system. The 7 steps concept of Autonomous Maintenance (operators) are similar to 7 steps of Planned (Effective) Maintenance (trades): “the left and right hand…

Read More »