Tools

5W1H, Why Why Analysis

1. 5W1H Who+What+When+Where+Which+How Classify the problem according to the 5Ws and 1 H explaining characteristics and trends 2. Understand the structure Flashlight definition diagram 3. Understand the principle and basic rules Principle The filament generate light due to heat Basic rules (Main rule) The filament has to receive an adequate…

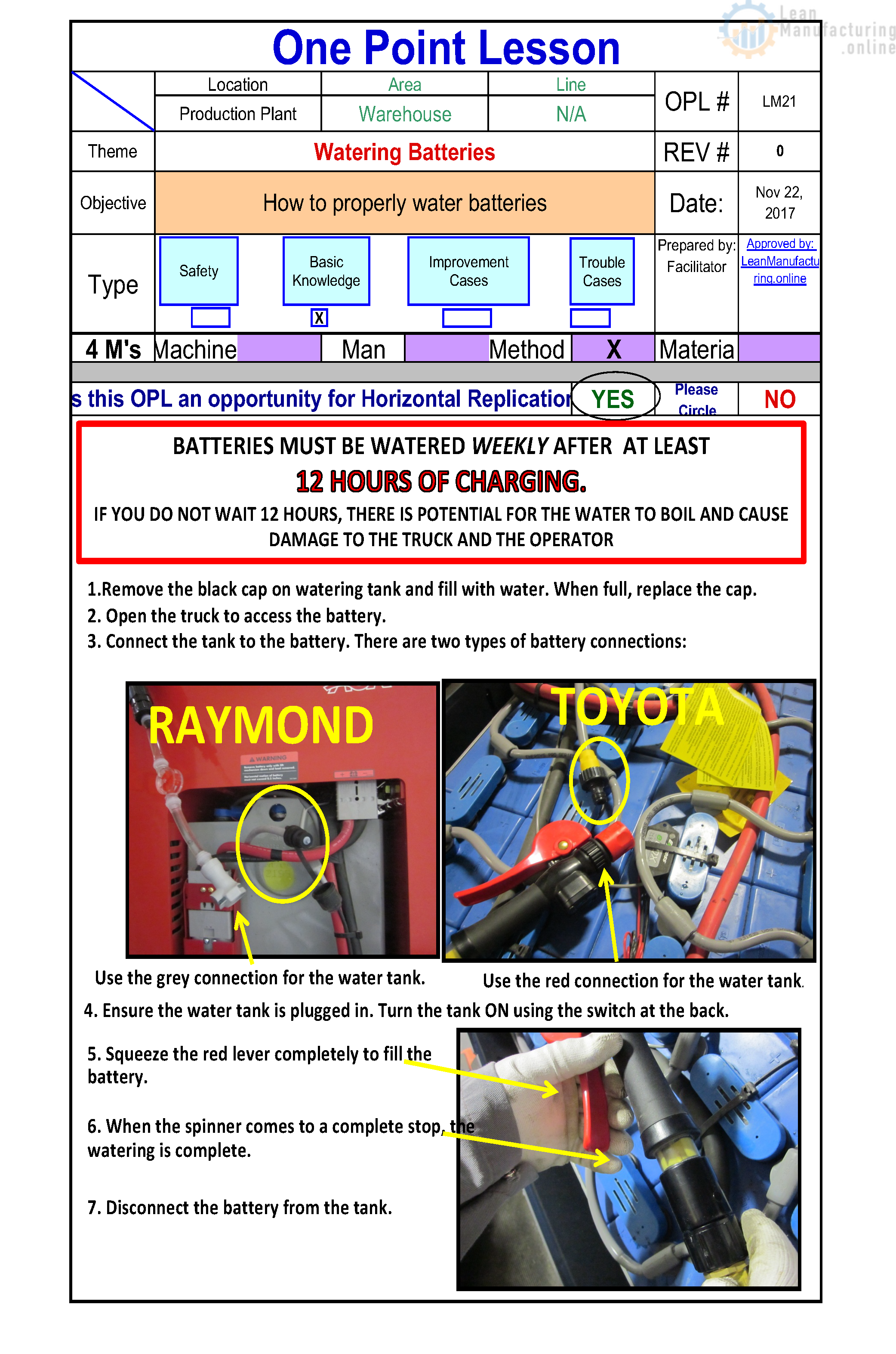

Read More »One Point Lesson – How to water forklift batteries

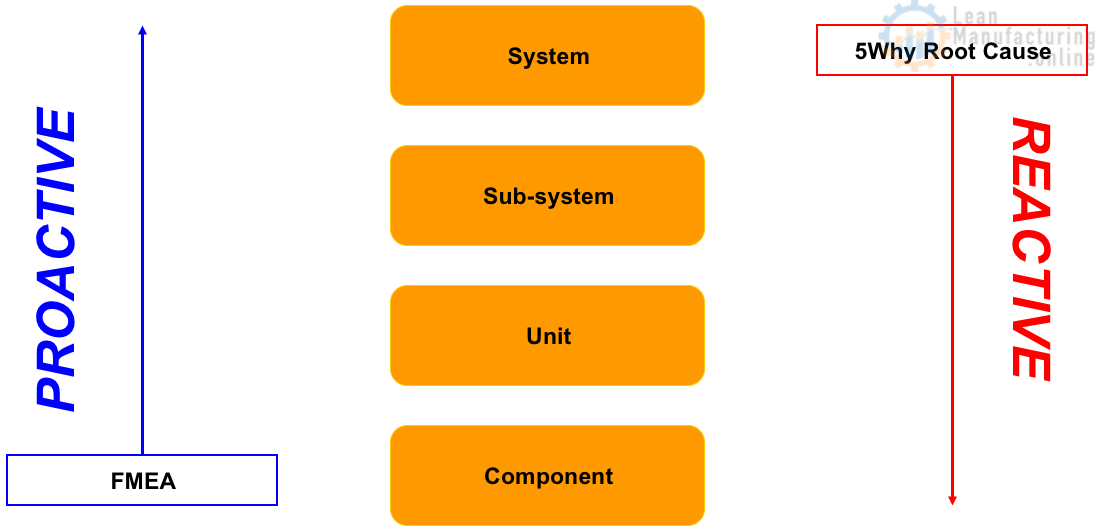

FMEA – Failure Mode and Effects Analysis

Procedure for analysis of potential failure modes within a system for classification by severity or determination of the effect of failures on the system. Types of FMEA FMEA + other tools & Techniques FMEA template Process Description System, Part No., Operation No. Process Purpose What has to be achieved, specification,…

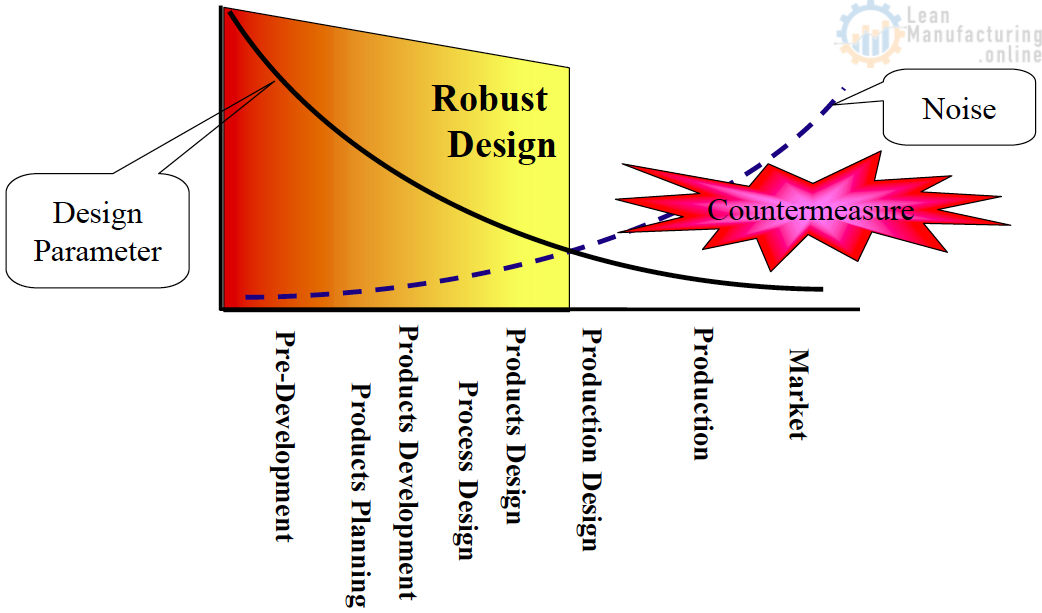

Read More »Robust Design, Quality Maintenance and Engineering. Part 2

4. Minimizing Variation 4.1 Variation (Consistency) means Temporal and Spatial Changes Quality engineering aims at minimizing the variation. then adjustment is made to achieve the target values. The variation is minimized first, and This is substantially different from the conventional method in which adjustment to the target values comes before…

Read More »