Tools

Visual Controls: Autonomous Maintenance – OPL Chain – Inspection

Visual Controls are very useful tools for a quick inspection to determine the condition of assembly to avoid or reduce downtime. One Point Lesson below gives examples of accessible chain and timing belt drive inspections.

Read More »P-M Analysis Audit Form

Subtotal for steps 1 – 4: 85% = 89; 100% = 105 Subtotal for steps 5 – 8: 85% = 34; 100% = 40 TOTAL SCORE: 85% = 123 points; 100% = 145 points

Read More »Electrical Safety One Point Lesson – Electrical Panels

All electrical panels and switches should be closed at all times. The only persons allowed to enter electrical panels are qualified electricians. No one else should ever enter an electrical panel. This OPL is only for reference – always follow safety rules prescribed by your local H&S department.

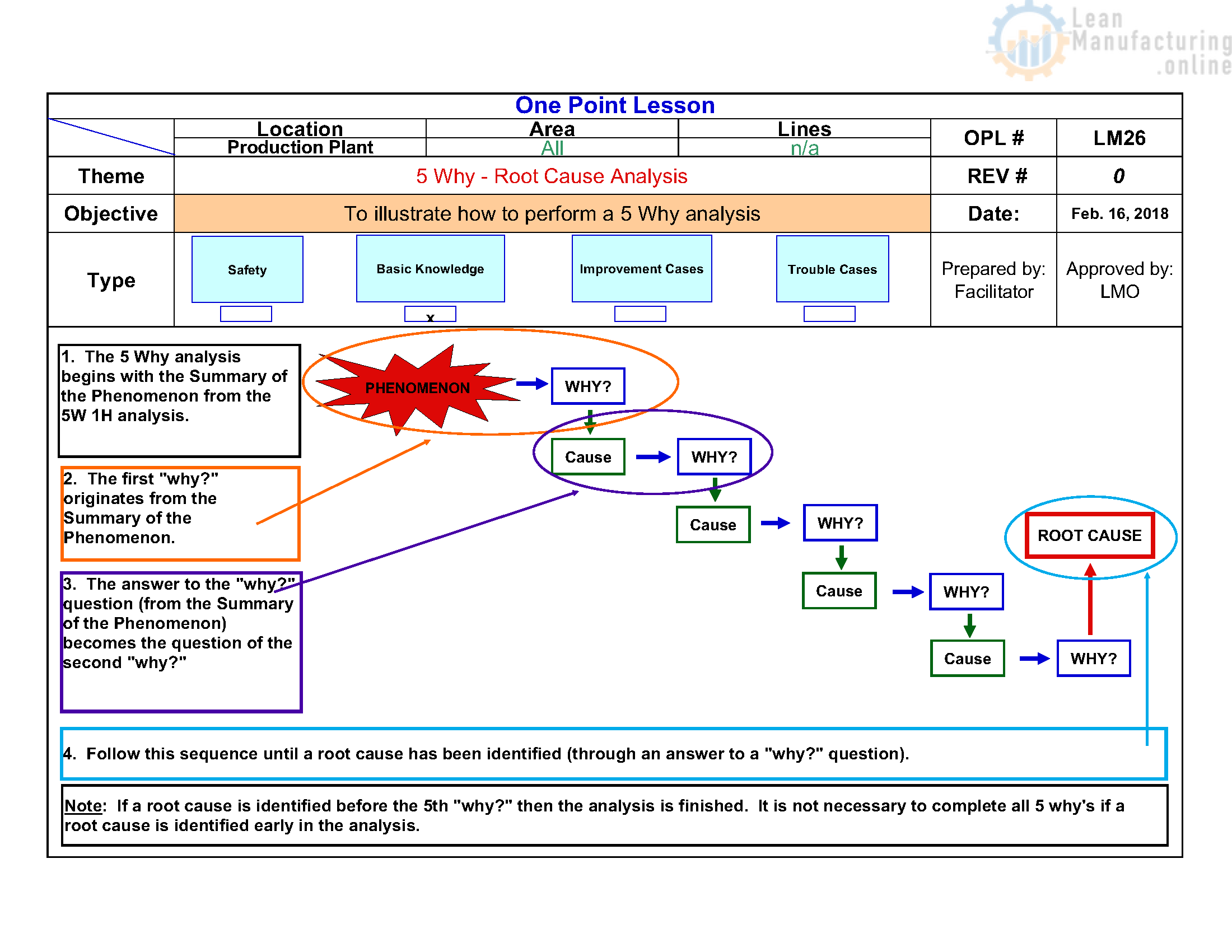

Read More »5 Why Root Cause Analysis (RCA) – One Point Lesson (OPL)

5 WHY Analysis is the key tool used to determine ROOT CAUSES for the Phenomenon identified in theCHECK Phase of CAP-Do. The 5 Why analysis begins with the Summary of the Phenomenon from the 5W 1H analysis. The first “why?” originates from the Summary of the Phenomenon. The answer to…

Read More »