Tools

DMAIC

DMAIC is a widely used problem-solving methodology for Define, Measure, Analyze, Improve, and Control. This methodology is commonly applied in Six Sigma projects and is designed to provide a structured approach to identifying and eliminating process defects. Each phase of the DMAIC process involves specific activities and tools that help…

Read More »One Point Lesson – Flat Belts Inspection – Autonomous Maintenance

Step 1: Clean the belt with a rag touching and observing the belt. Step 2: Look if flat belt is worn or cracked.

Read More »Inspection Steps for Chains and Sprockets – Visual Standards Inspections

Step 1: Clean the sprocket with a rag touching and observing the sprocket. Step 2: Look for the following abnormalities: Worn teeth Misalignment Abnormality 1: Worn teeth teeth should not be rounded,teeth should not be chipped. Abnormality 2: Misalignment The sprocket must be aligned and perfectly perpendicular to the axis of…

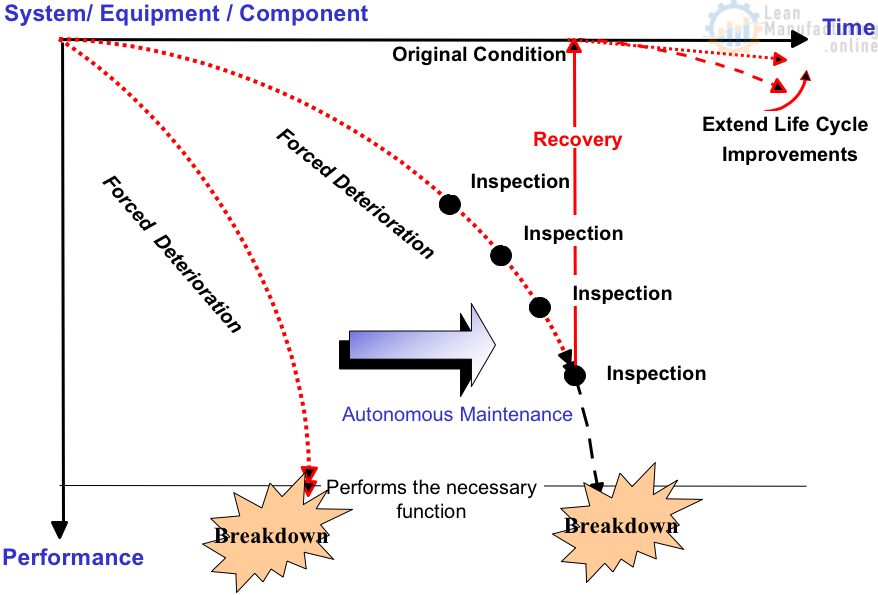

Read More »Approaching Zero Breakdowns by advancing Breakdown analysis

What is Maintenance? Maintenance: It is a set of developed, organized and administered activities with the aim to economically viable ensure the operational status of a specific system. The 7 steps concept of Autonomous Maintenance (operators) are similar to 7 steps of Planned (Effective) Maintenance (trades): “the left and right hand…

Read More »