Tools

Kanban and Just-In-Time Manufacturing

JIT manufacturing In the mid twentieth century, the United States assembled a considerable measure of extensive distribution centers. That is the reason for the vast majority of the twentieth century, you see the U.S. depending on substantial stock assembling. An auto organization could fabricate one thousand autos, and after that…

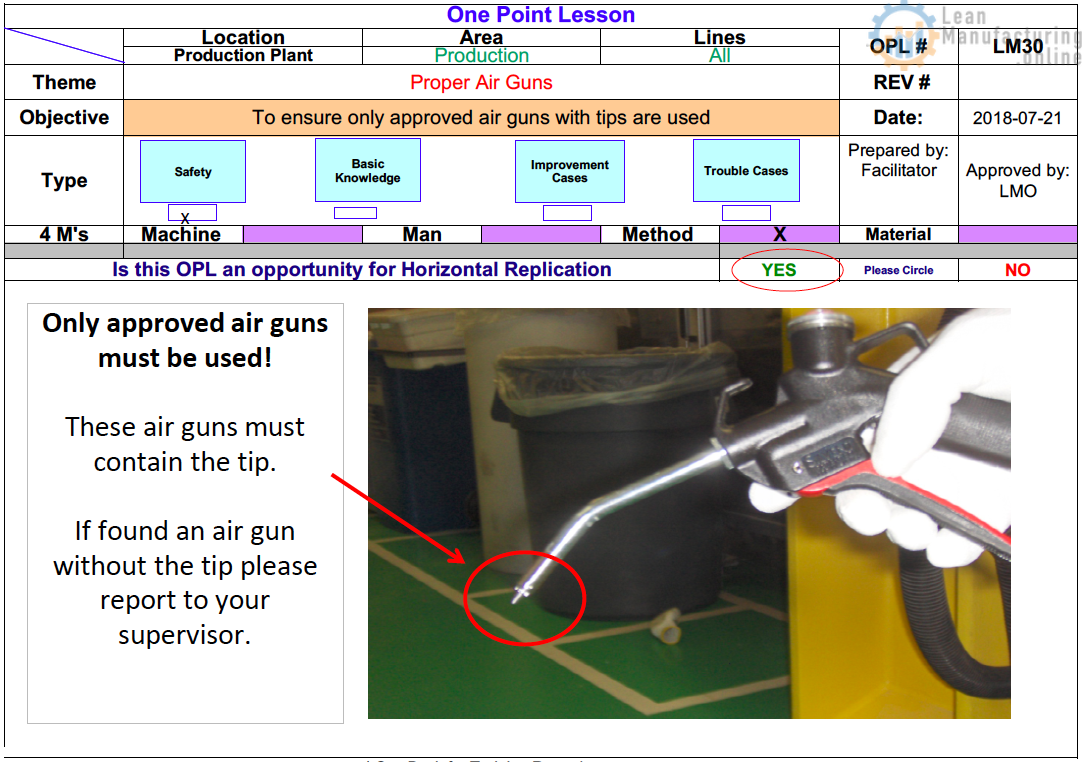

Read More »One Point Lesson – OPL – Compressed Air Safety – Usage of restricted air guns for cleaning activities

Usage of compressed air is very effective, however is very dangerous if not handled properly. Recommended to use air with restricting nozzle, reduces safety risk without loosing cleaning effectiveness. All approved air guns must have safety tip, if during pre-operational inspection found that air gun is missing nozzle, please report…

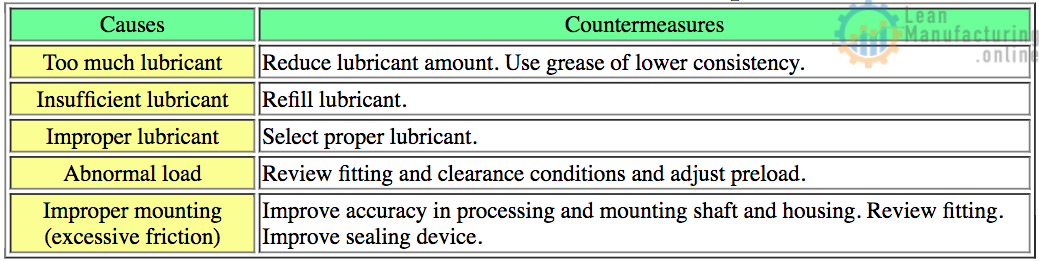

Read More »Bearing failures – Root Cause Analysis and countermeasures

When a bearing is used under ideal conditions, it will only be damaged by rolling fatigue. Damage due to rolling fatigue may occur very early, however. If damage is found on a bearing, it is important to examine the phenomenon properly and identify the causes, even if the damage is…

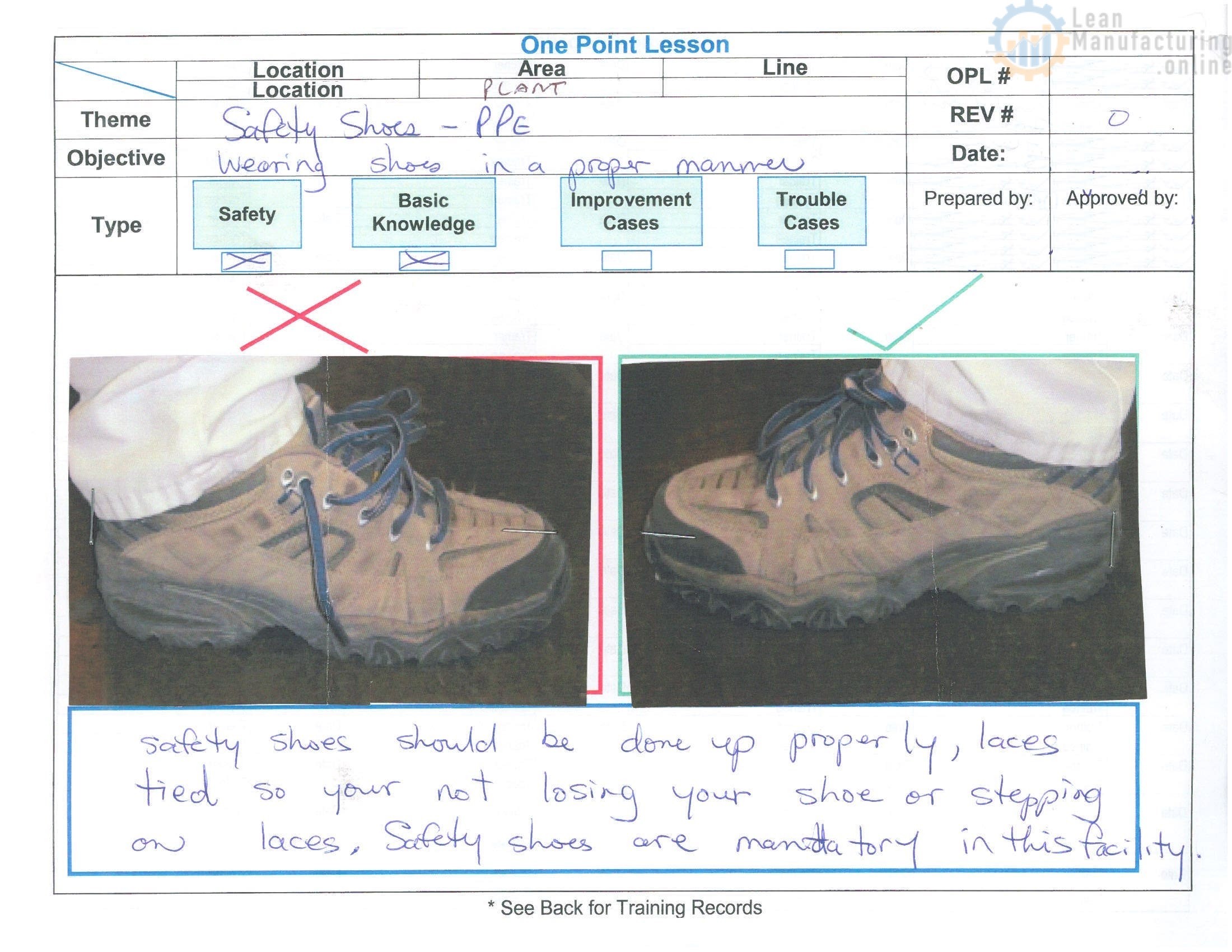

Read More »One Point Lesson – OPL

What is an OPL? A tool to convey information. Designed to enhance knowledge and skills in a short time, at the right time, whenever needed. To upgrade levels of expertise by having individuals study, learn and then train others in the knowledge or skill. Who Creates OPL’s? Everyone! Operators, Mechanics,…

Read More »