Tools

Lessons Learnt as a communication tool

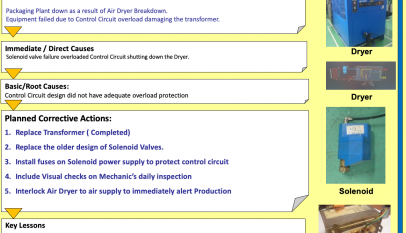

Another great tool to create short but meaningful communication is Lessons Learnt. It can be used to communicate Safety, Quality or Productivity issues to all Team Members. Goal is to explain what happened and how to avoid it from happening in the future. Lessons Learnt Principles applied are to: Take…

Read More »Broken Parts Museum – Analyzing and Preventing Breakdowns due to Forced Deterioration

5 Why Analysis Autonomous Maintenance Blog OPL Root Cause Analysis Training World Class Manufacturing

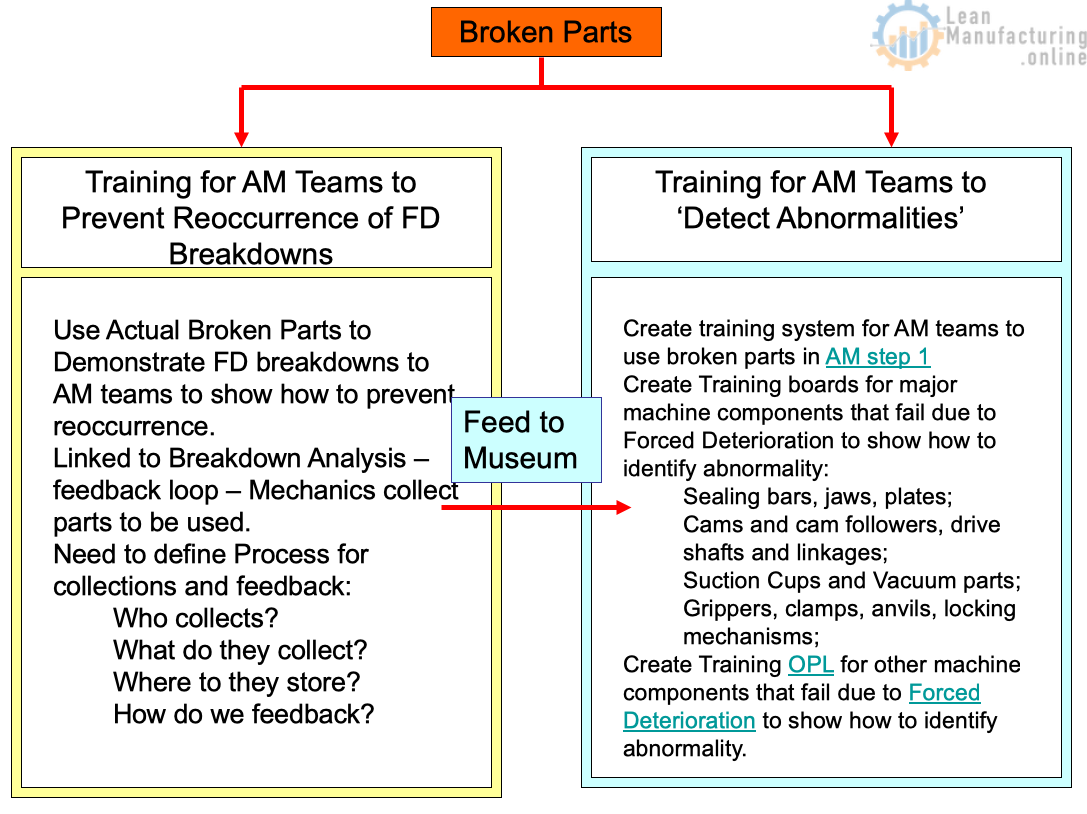

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members. Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to…

Read More »Capdo form tracking – Check Analyze Plan Do

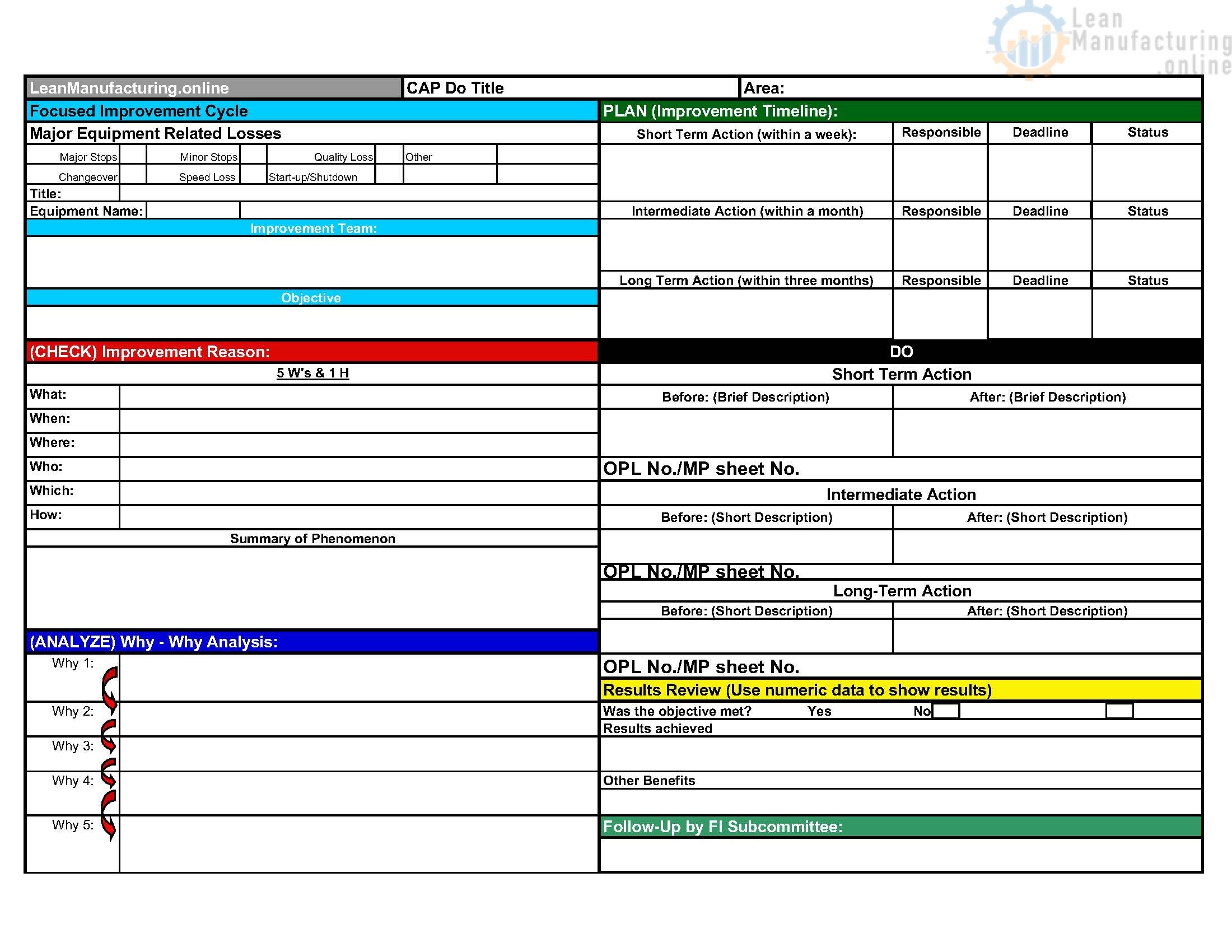

Ready to start your own Focused Improvement Project? CAP-Do will be a fast and efficient approach to achieving KPIs and targets. To capture and track the progress, you will need a CAP-Do template. The template can be downloaded here If you require one in Excel spreadsheet format, don’t hesitate to…

Read More »P-M or 4M analysis

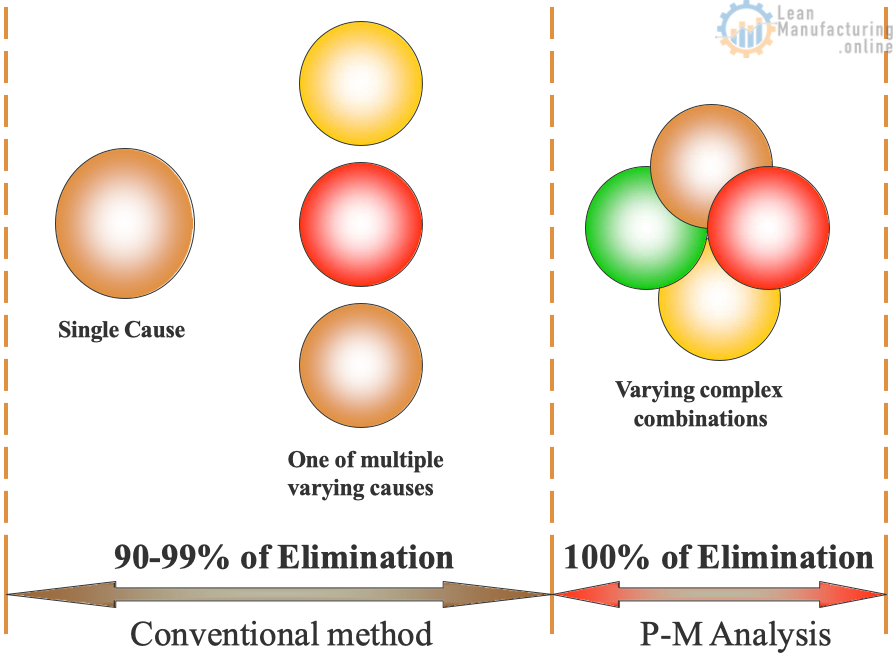

Chronic & Sporadic Losses Sporadic losses occur suddenly and infrequently, they result from a single cause that is relatively easy to identify and solve; Chronic losses, on the other hand, live up to their name by resisting a wide variety of corrective measures. P-M Analysis Single causes that vary constantly…

Read More »