Tools

Activity Boards

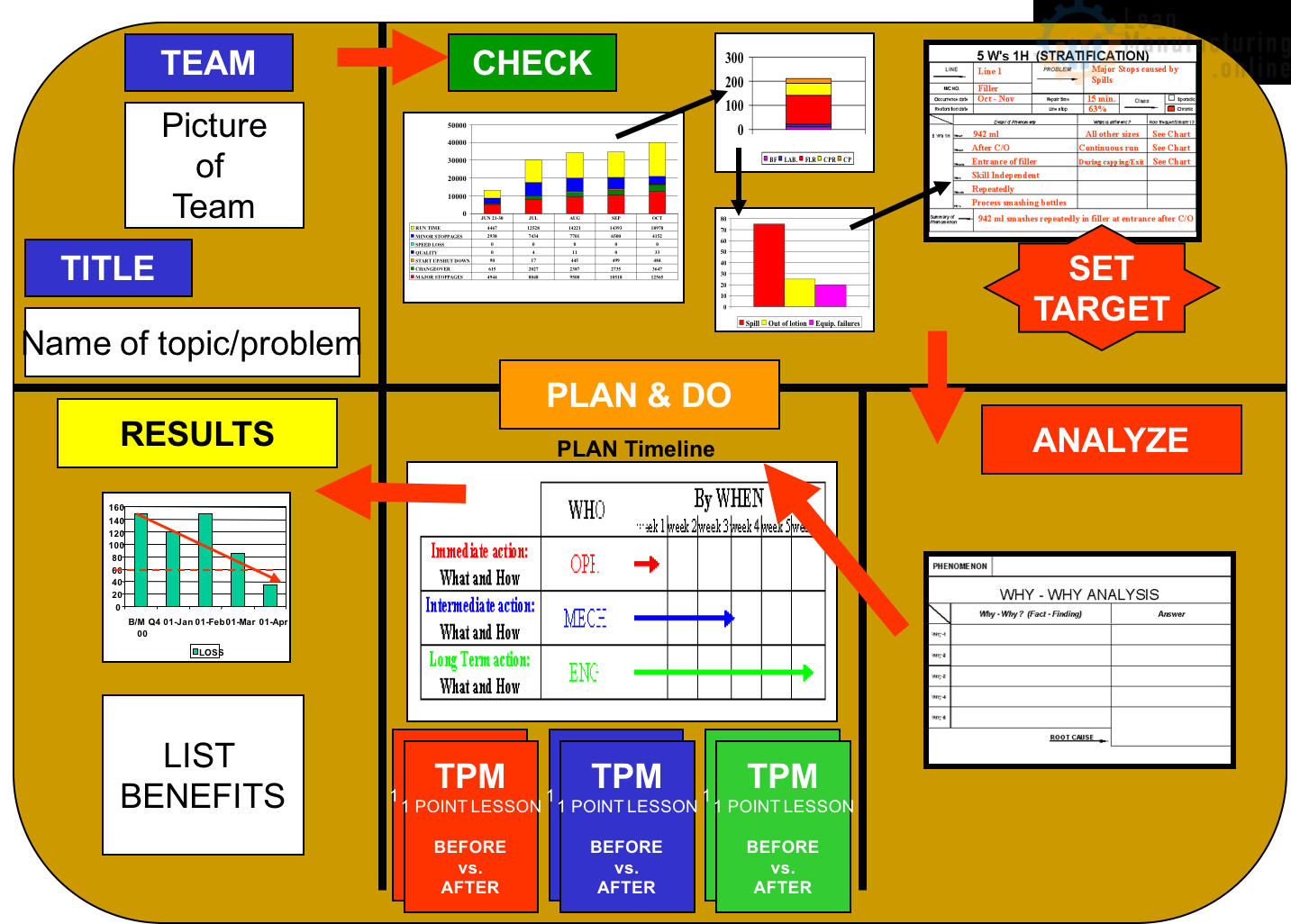

Activity Board Objectives Visual representation of our goals, activities, and results. A consistent method of communication. Through the construction and presentation of an Activity Board, Teams’ understanding of content is reinforced. Activity Boards are training material. Components Show Team Vision, Methodology, Pictures, Names, Roles, Goals, Results, Safety Message, Team Learnings.…

Read More »What are F-tags?

FUGUAI = DEVIATION<->ABNORMALITY Functional DefectsPollutionDifficult to Access/ObserveHard to Load/OperateUnsafeSafety, Health, Environment, Quality (SHEQ) “unfriendly”Undesirable Tasks “F” Tags are used to highlight Deviations, Faults, or Abnormalities. 3 Types of F-Tags Safety Everyone writes safety F-Tags for everyone. Mechanics or operators can close these—yellow colour. Operator Operator F-Tags are Blue.Operator means anyone…

Read More »12 Step Kaizen Toolkit

The full process described here: 12 Step Kaizen Story Step # Step Explanation Form Name 1 Identify The Situation 1) Charter Team 2) Collect the available Data 3) Classify The Losses Step 1 – Team Charter 2 Justify The Situation 1) Stratify The Losses 2) Select the Subject 3) Verify…

Read More »Failure Mode and Effects Analysis

We should be able to determine whether we need to put detection in place in certain areas and determine how to recover from certain fault conditions.

Read More »