Supply Chain

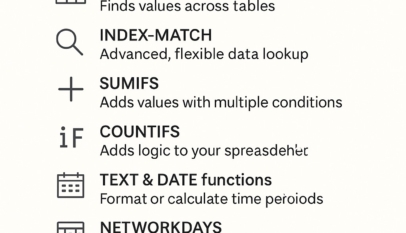

How to Use Excel to Boost Supply Chain Efficiency

Discover the essential Excel formulas that supply chain planners use to save time, reduce errors, and make smarter decisions. From VLOOKUP to NETWORKDAYS, these tools can transform raw data into actionable insights that drive efficiency and accuracy.

Read More »Planned Maintenance Case Study, Food Processing Plant

Discover how a food processing plant significantly improved its efficiency and reduced equipment breakdowns by implementing a planned maintenance approach. With a 40% reduction in breakdowns and a 20% increase in overall equipment effectiveness (OEE), this case study highlights the importance of a proactive and well-structured maintenance program for enhancing…

Read More »Supplier Quality Management

Improve your supply chain and increase your operational efficiency with effective Supplier Quality Management. Learn how to assess and select the right suppliers, establish quality requirements, perform audits and inspections, manage nonconformances, and measure performance. With these strategies, you can reduce costs, improve delivery times, enhance customer satisfaction, and boost…

Read More »LinkedIn Learning: An In-Depth Guide to Its Cost and Features

Blog Courses Education Lean Six Sigma Process Excellence Project Management Supply Chain TPM TPS World Class Manufacturing

LinkedIn Learning is an online learning platform that offers a variety of courses and tutorials on topics such as business, technology, creative arts, and more. With its flexible pricing options, including a free trial, and expert instructors, the platform provides users with a valuable learning experience. Whether you're looking to…

Read More »