Safety

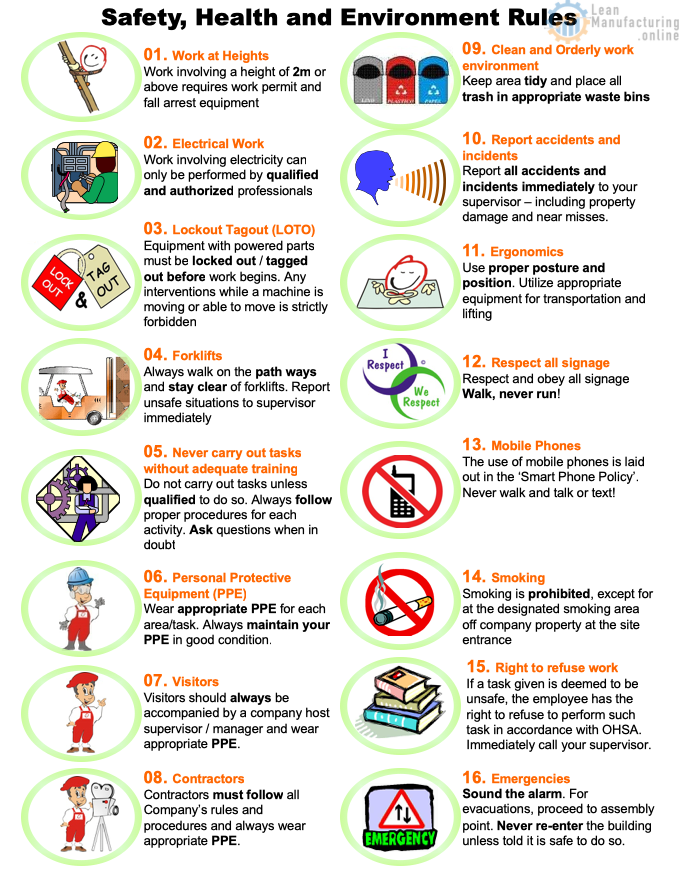

Safety, Health and Environment Rules – SHE Pillar

Every manufacturing facility should have a set of SHE rules for workers, visitors/and contractors. Rules must be designed in accordance with company policies as well as local legislation. Please see below examples of Safety, Health, and Environment Rules: Work at Heights Work involving a height of 2m or above requires…

Read More »Safety, Health, and Environment TPM pillar

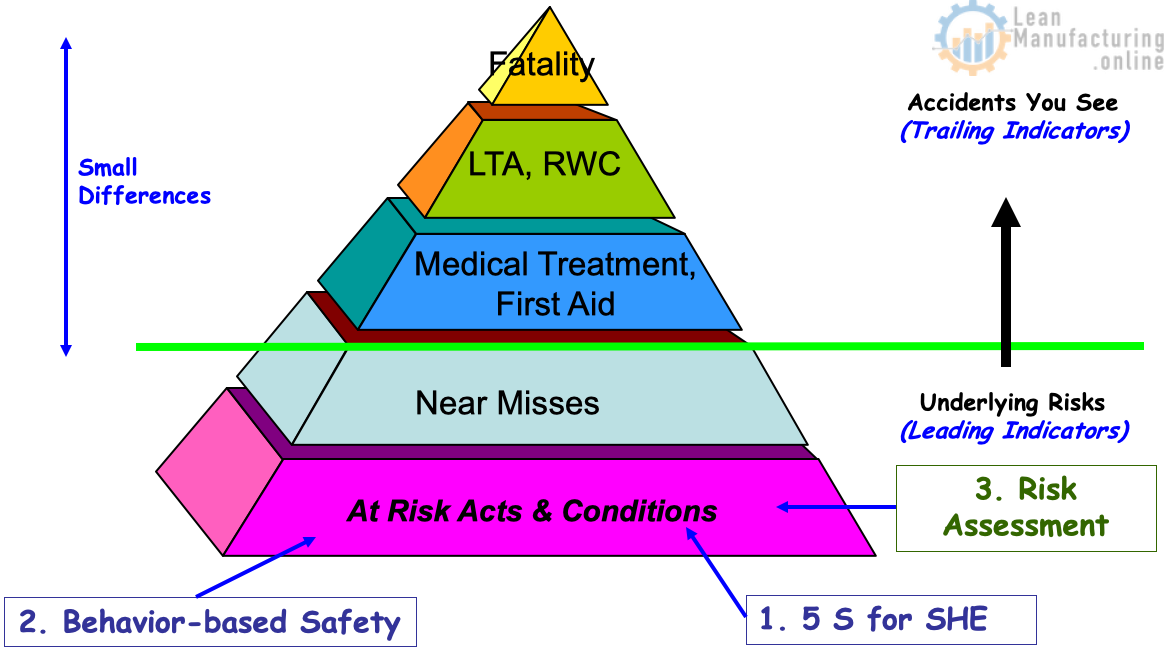

SHE pillar vision is to cultivate a Continuous Improvement culture that achieves a sustained record of Safety, Health, & Environmental excellence & realizes our vision: ZERO accidents, ZERO incidents, ZERO losses. The SHE Pillar is the cornerstone TPM Pillar that supports and lends stability to the overall continuous improvement process…

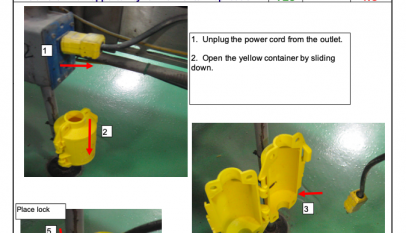

Read More »OPL – Safely locking out the tape machine or any other equipment with plug

Have a mobile piece of equipment on production floor that is not hardwired? Usually these types of equipment don’t have lockable switch but power source need to LOTO to work safely. Simply attach Electrical Plug Cover Lockout to frame of the equipment, so it would be there when LOTO will…

Read More »Autonomous Maintenance Step 0

What is Step 0? Step 0 is the Preparation Phase for AM, specifically with regard to Safety. Safety Comes First! Objectives of Step 0: 1.Ensure safe work practices in AM 2. Get better understanding of equipment 3. Learn TPM tools Ensuring Safe Work Practices Personal Protective Equipment (PPE) Identify Sources of…

Read More »