Lean

6 Elements of Process Excellence

First let’s review “what” is Process Excellence, or first three elements of the process: Customer Value Stream (CVS) processes that run flawlessly from one end to another; delivering value to the customer when they want to where they wanted to how they wanted with little or no waste. Root Cause…

Read More »Major Stops – The Real Costs

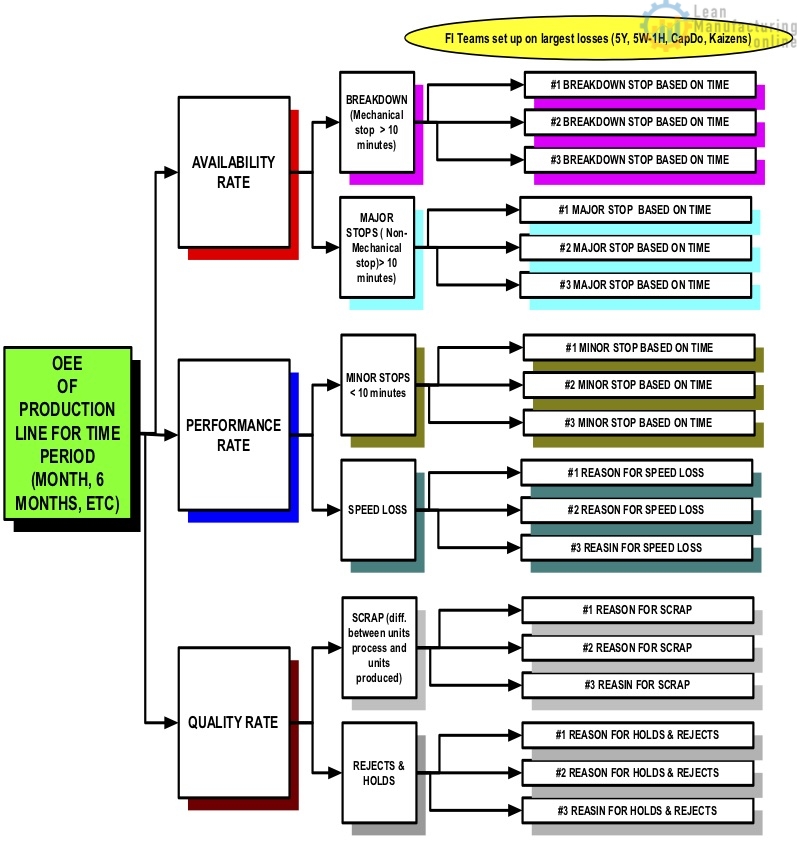

Plant reliability is the key underpinning of an efficient supply chain. Without the ability to produce what is needed, when it is needed and, in the quantity needed, the entire Supply Chain must cover itself by placing inventory at critical areas thus driving up working capital and total costs. Excessive…

Read More »DMAIC – Measure – Stakeholder Analysis

Definition of Stakeholder Any individual or group can either influence or might be affected by the project. Their support is key to the success of the project. Some examples of key stakeholders: CustomersOperations ManagementHourly and staffSuppliers and end-usersRegulatory Body A stakeholder can offer both support and resistance: Technical or functional…

Read More »Introduction to Lean Principles

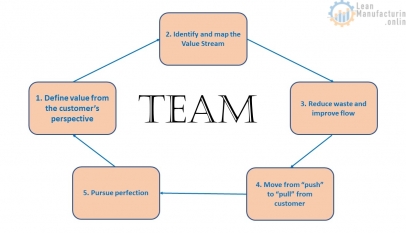

Principle #1. Specify and Focus on Value Any activity or task that transforms a product or service in such a way that the customer is both aware of it and willing to pay for it;Can be defined only by the ultimate customer;It is meaningful only when expressed in terms of…

Read More »