Lean Manufacturing

Streamlining Business Processes with DMASC: A Comprehensive Guide to Standardization Projects

Discover the power of DMASC, a process improvement methodology designed for standardizing processes and improving consistency across organizations. Ideal for service industries, DMASC (Define, Measure, Analyze, Standardize, Control) focuses on establishing standard processes and ensuring adherence by all staff members. This approach leads to enhanced efficiency, reduced errors, and streamlined…

Read More »Optimizing Changeover Times: A Lean Six Sigma Approach to Enhancing Food Packaging Line Efficiency

"Optimizing Changeover Times" is a Lean Six Sigma project focused on enhancing food packaging line efficiency by reducing changeover times between SKUs. Through the DMAIC framework, the project aims to minimize downtime, increase throughput, and deliver cost savings. Emphasizing data-driven decision-making and continuous improvement, this initiative seeks to set a…

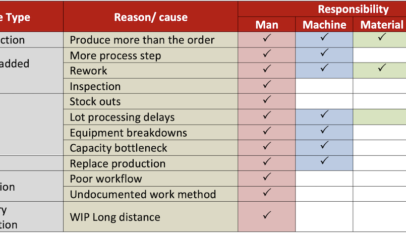

Read More »12 Wastes to Eliminate in Product and Process Development

Discover how to boost efficiency in manufacturing by identifying and eliminating 12 common wastes in product and process development. This comprehensive guide covers strategies for reducing overproduction, waiting time, transportation waste, and more, paving the way for increased competitiveness and long-term success in the manufacturing sector.

Read More »Lean Leadership: The Importance of Standard Work

Leader Standard Work (LSW) is more than a checklist—it’s a disciplined system that helps leaders balance control, improvement, and coaching. Learn how to design your own LSW routine to drive consistency, reduce chaos, and build a culture of continuous improvement.

Read More »