Lean Manufacturing

What if your morning coffee receipt looked like this?

Swathi Mohan discusses the importance of identifying and eliminating 'Waste' in business processes, which includes any activity not adding value to the customer. She categorizes Waste into seven types, according to lean manufacturing principles: Correction, Overproduction, Motion, Movement, Inventory, Waiting, and Processing. Mohan also shares suggestions for reducing each type…

Read More »How do you ensure that your quarterly Objectives are both ambitious and achievable?

Balancing ambitious and achievable quarterly objectives involves aligning them with strategic goals and ensuring they're SMART (Specific, Measurable, Achievable, Relevant, Time-bound). Using historical data and industry benchmarks can help set realistic targets. Employee involvement in setting these objectives can foster a sense of ownership and motivation. Regular review and adjustments…

Read More »Unravelling the Intricacies of the Toyota Production System vs. Lean Manufacturing

The TPS, the progenitor of Lean Manufacturing, is deeply ingrained within Toyota's culture, reflecting their relentless pursuit of improvement. Lean, on the other hand, coined by John Krafcik in his master’s thesis at MIT, has been embraced worldwide, transforming industries with its systemic approach to waste reduction and process optimization.

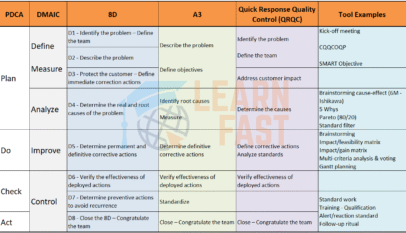

Read More »A Comparative Analysis of Popular Continuous Improvement Methodologies: PDCA, DMAIC, A3, QRQC and 8D

Explore the differences between four popular continuous improvement methodologies - PDCA, DMAIC, A3, and 8D. This blog post offers a comprehensive comparison, examining their unique steps and applications, to help you choose the most suitable approach for your organization's improvement journey.

Read More »