Lean Manufacturing

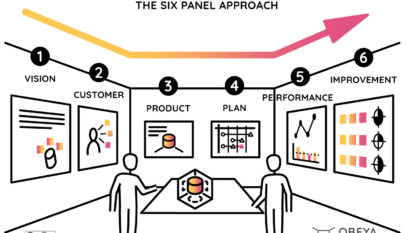

Maximizing Operational Efficiency with Obeya and Gemba

Discover how the Obeya room, Gemba walks, and KPI cascades can transform your organization's efficiency by aligning leadership, metrics, and continuous improvement efforts. Learn about structured problem-solving, huddle cadences, and the importance of cross-functional collaboration to drive success.

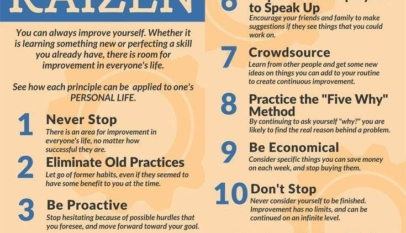

Read More »How to Transform Your Business with Kaizen Principles

Discover how the Kaizen methodology can revolutionize your business operations by eliminating inefficiencies, fostering continuous improvement, and boosting morale. This guide breaks down the step-by-step process of implementing a successful Kaizen workshop while sharing an inspiring story of transformation in unexpected circumstances.

Read More »Achieving Manufacturing Excellence: The Right First Time Approach

Discover how Right First Time (RFT) principles can revolutionize your manufacturing process by reducing defects and improving quality from the outset. Learn key strategies to enhance your RFT score and boost efficiency.

Read More »Mastering Lean Manufacturing: Tackling Overburden for Optimal Performance

Discover key insights into mastering overburden in lean manufacturing. This article delves into the nuances of workplace efficiency, focusing on strategies like workload balancing, ergonomic interventions, and consistent management communication. Understand the impact of these approaches on employee well-being, productivity, and overall operational excellence. Dive into practical tips for creating…

Read More »