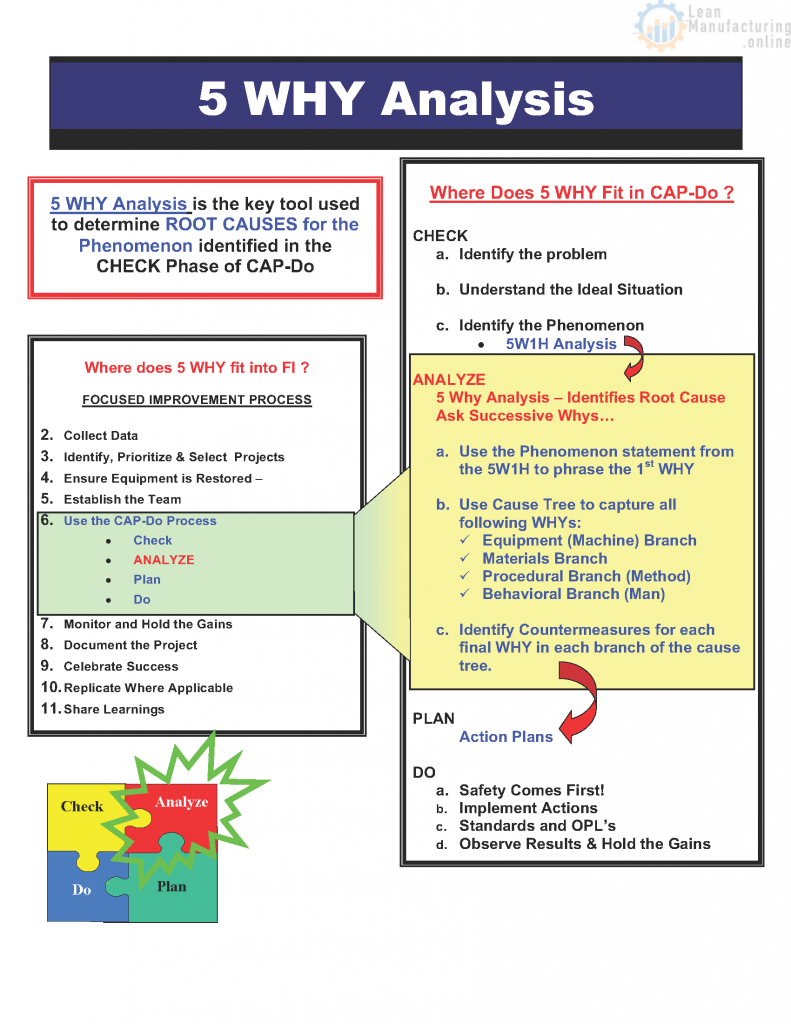

5 WHY Analysis is the key tool used to determine ROOT CAUSES for the Phenomenon identified in the

CHECK Phase of CAP-Do.

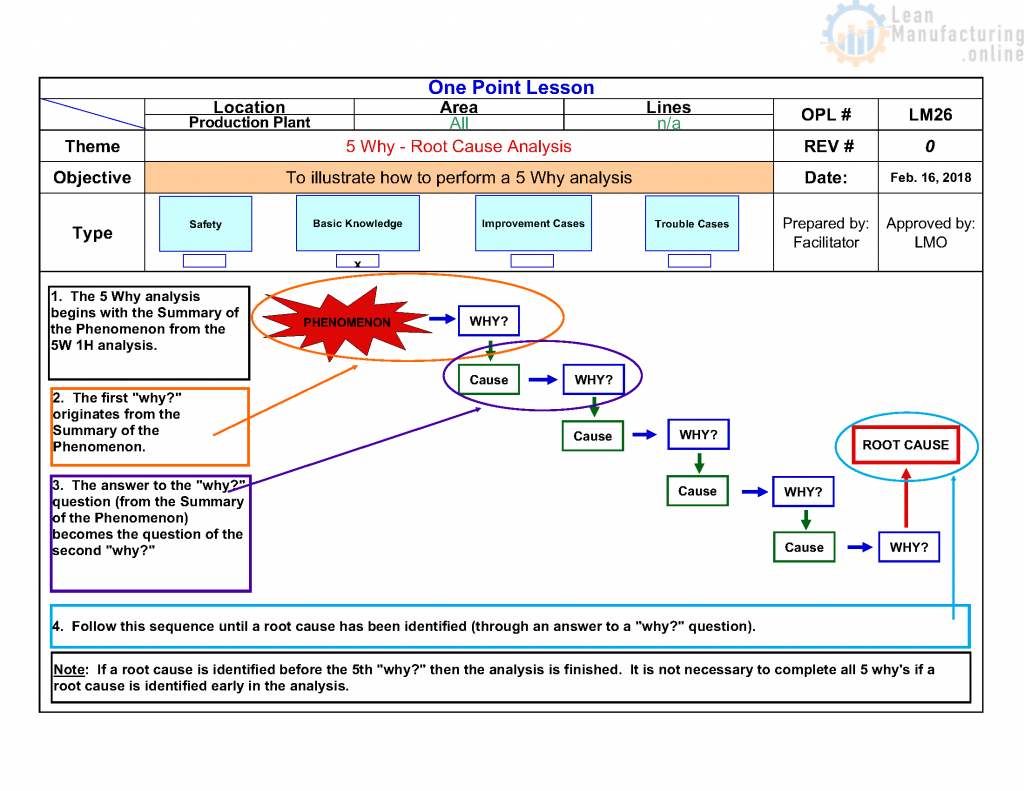

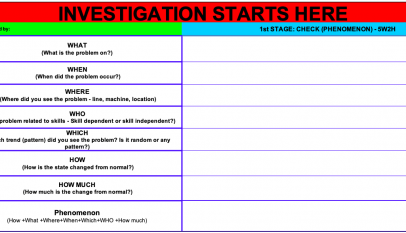

- The 5 Why analysis begins with the Summary of the Phenomenon from the 5W 1H analysis.

- The first “why?” originates from the Summary of the Phenomenon.

- The answer to the “why?” question (from the Summary of the Phenomenon) becomes the question of the second “why?”

- Follow this sequence until a root cause has been identified (through an answer to a “why?” question).

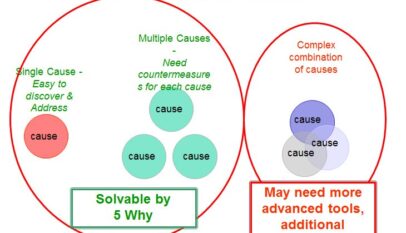

Note: If a root cause is identified before the 5th “why?” then the analysis is finished. It is unnecessary to complete all 5 whys if a root cause is identified early in the analysis.

Very powerful tool indeed and it helps you for analysis steps in no matter what is the project’s subject