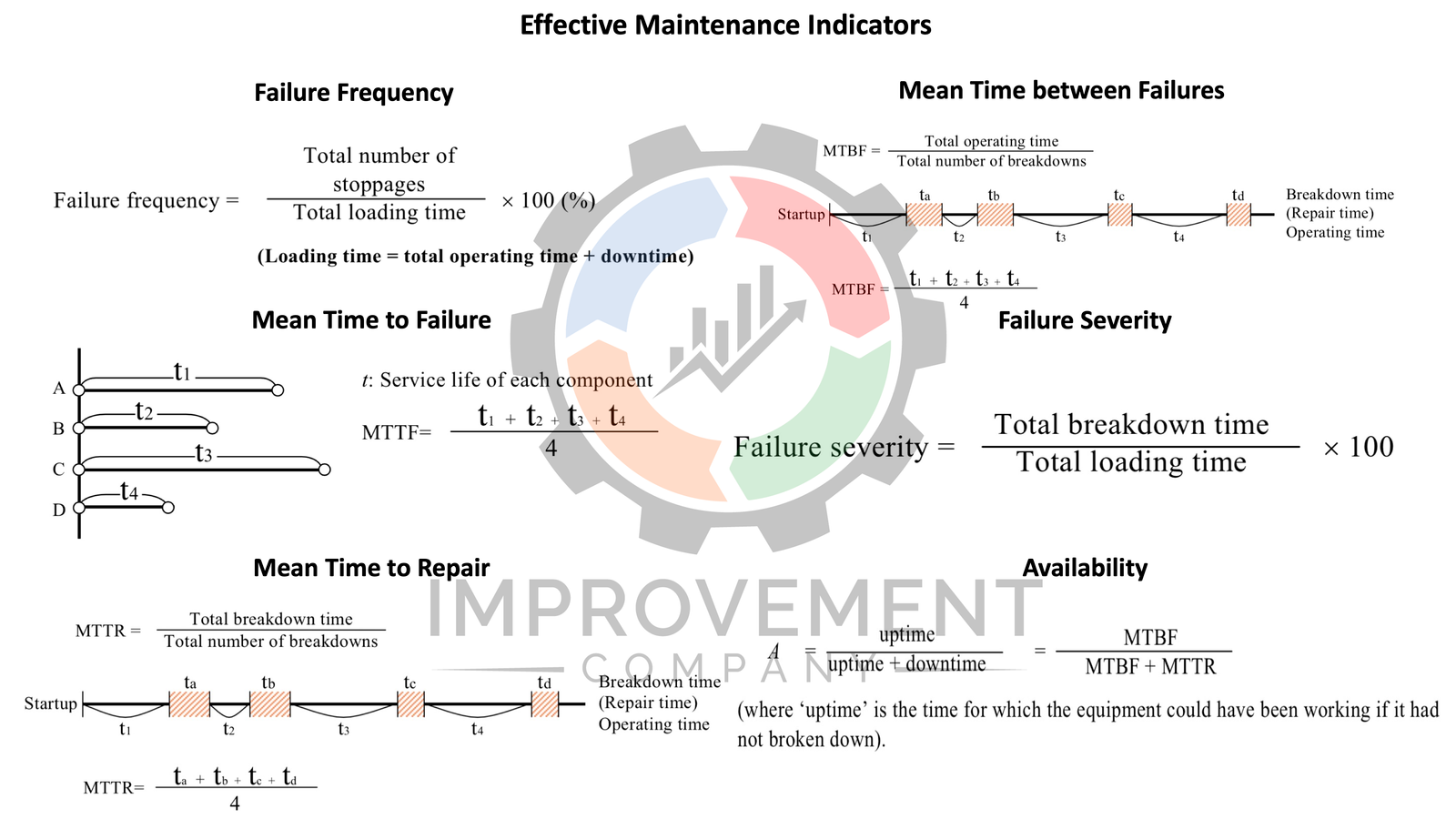

Planned Maintenance Indicators: A Guide to Improved Equipment Reliability

Effective maintenance is critical to the success of any manufacturing operation. It helps to keep equipment running smoothly, reduces downtime, and improves overall productivity. One of the key components of effective maintenance is planned maintenance, which involves scheduling regular maintenance activities in advance to prevent equipment failures and minimize downtime. In this blog post, we will explore the importance of planned maintenance indicators and how they can help to improve equipment reliability. What are Planned…