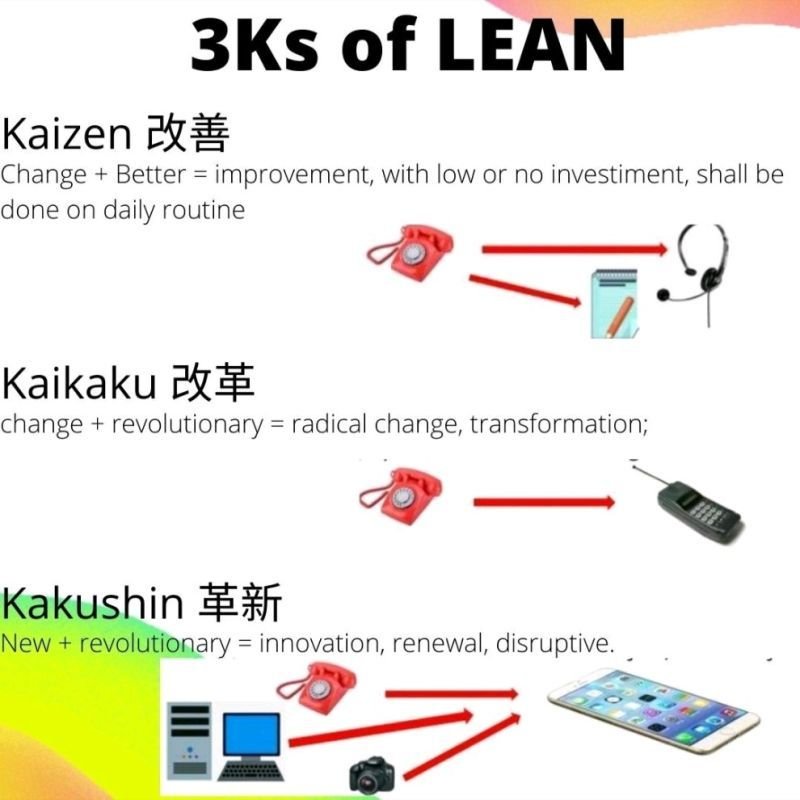

The 3Ks of Lean – Kaizen, Kaikaku, and Kakushin

The 3Ks of Lean manufacturing are principles that are focused on continuous improvement, transformation, and innovation. Kaizen, which means “continuous improvement,” encourages organizations to constantly strive for small, incremental improvements in their processes and products. Kaikaku, or “transformation,” involves making significant changes to a process or system to achieve breakthrough improvements. Finally, Kakushin, or “innovation,” involves creating new products, processes, or systems that provide significant improvements in quality, efficiency, or effectiveness. These principles provide a framework for organizations to achieve greater efficiency, quality, and competitiveness through continuous improvement, bold transformation, and innovative thinking.