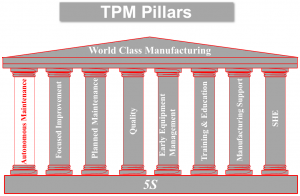

Total Productive Maintenance focuses on increasing productivity. By measuring the Overall Equipment Effectiveness, breakdowns, and other losses like sub-standard quality, are identified and resolved.

Low OEE? High Production cost? Take our free TPM Instructor course and start saving today!

TPM Instructor Course presentations that will cover all major aspects of Total Productive Maintenance. It can be used to create training presentations for your teams when rolling out, for example, Autonomous Maintenance.

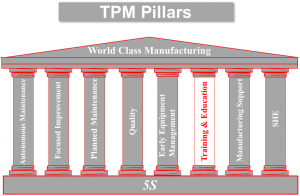

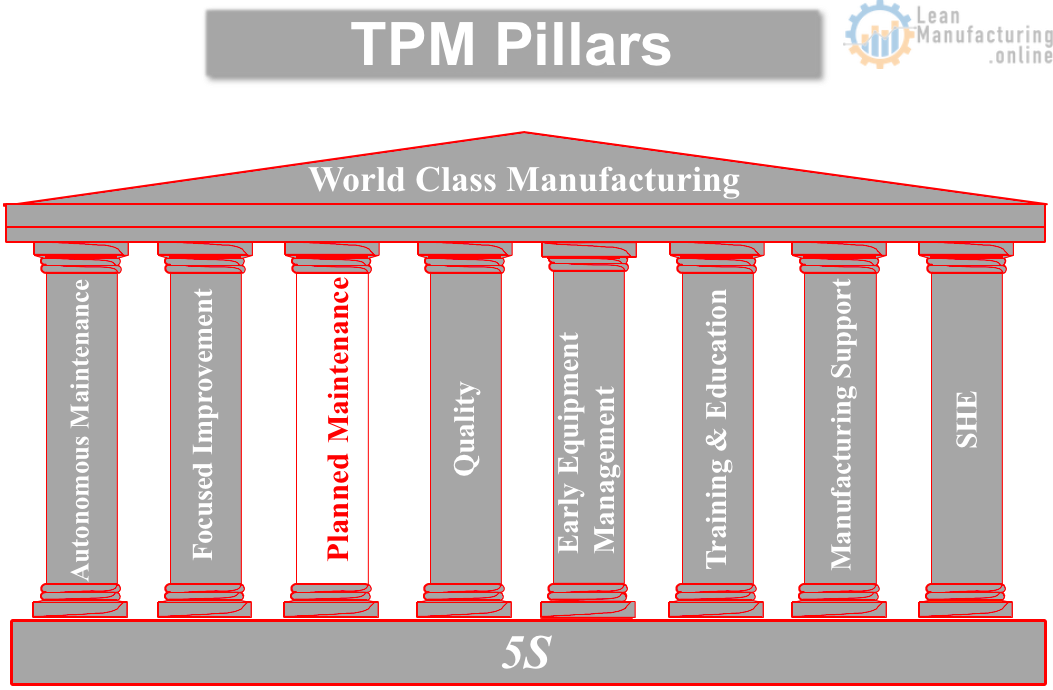

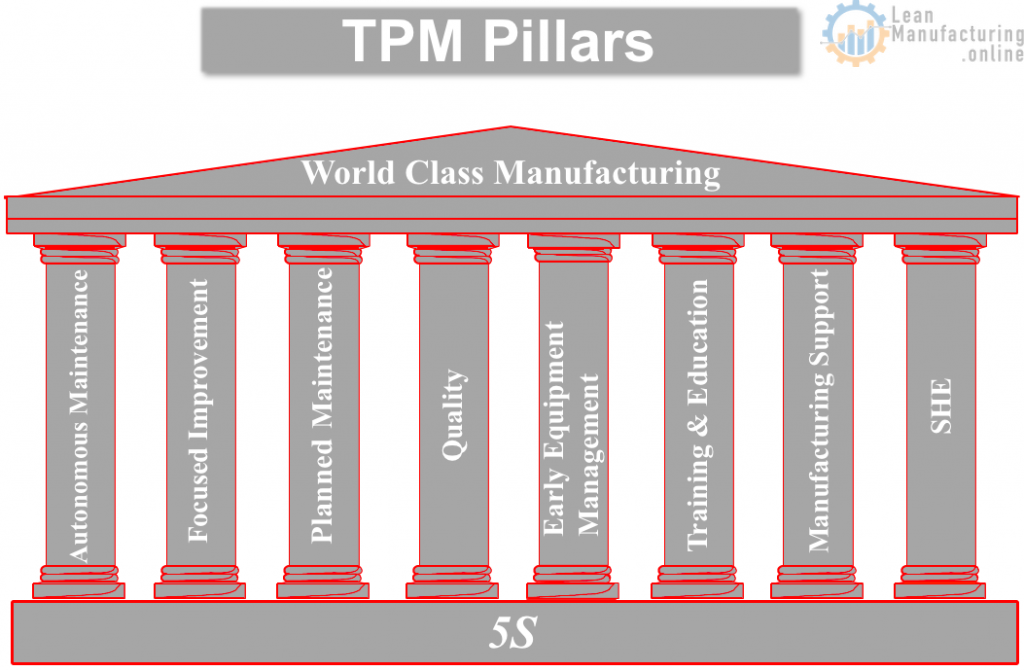

- Autonomous Maintenance

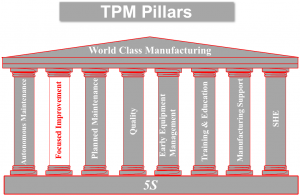

- Focused Improvement

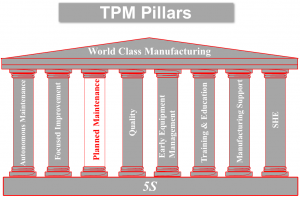

- Planned Maintenance

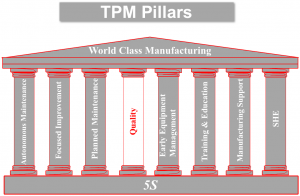

- Quality

- Early Equipment Management

- Training and Education

- Manufacturing Support

- Safety, Health, and Environment

Planned Maintenance (PM) or Effective Maintenance (EM)

Quality (Q) or Quality Maintenance (QM)

Early Equipment Management (EEM)

Education and Training (E&T) or Training & Development (T&D)

Manufacturing Support (MS) or Administration/TPM Office

Safety, Health & Environment (SHE)

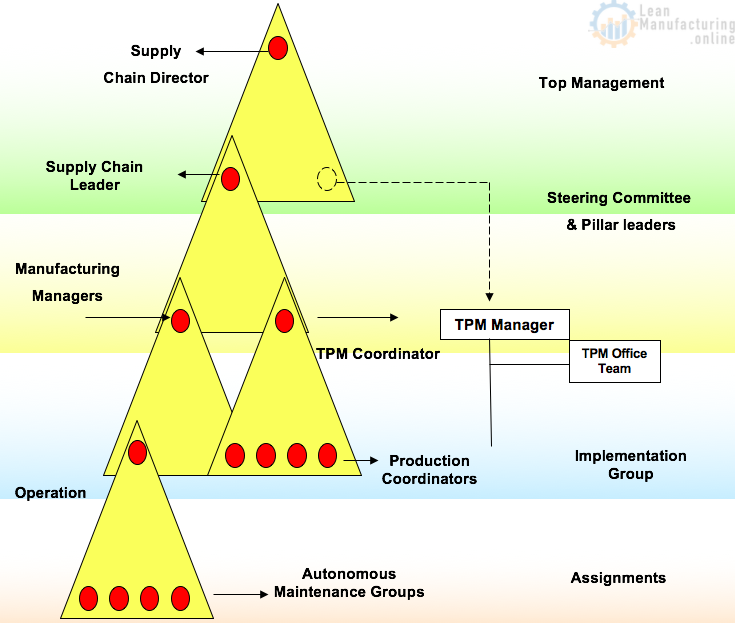

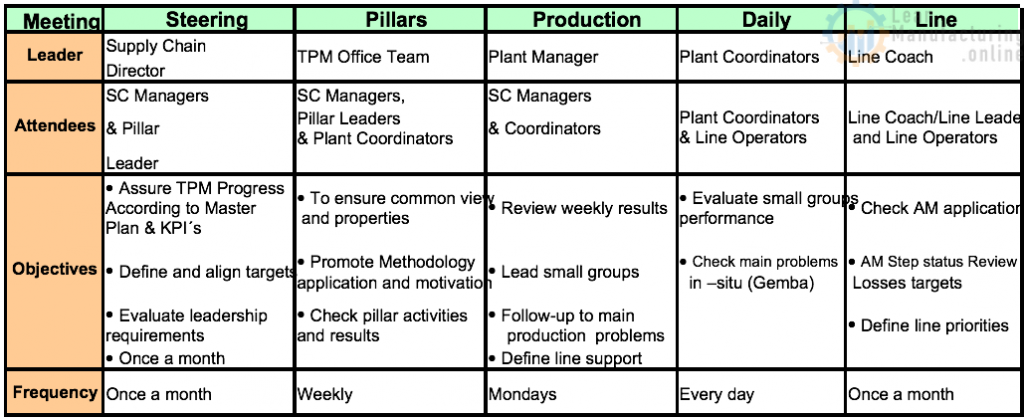

TPM Meetings

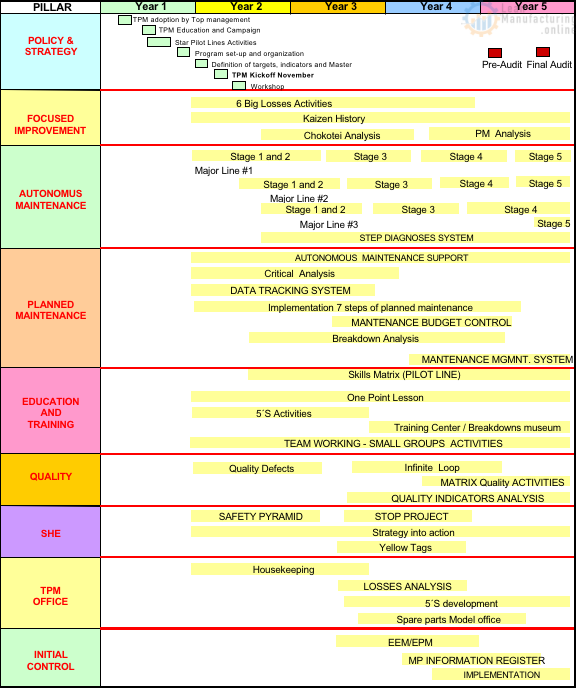

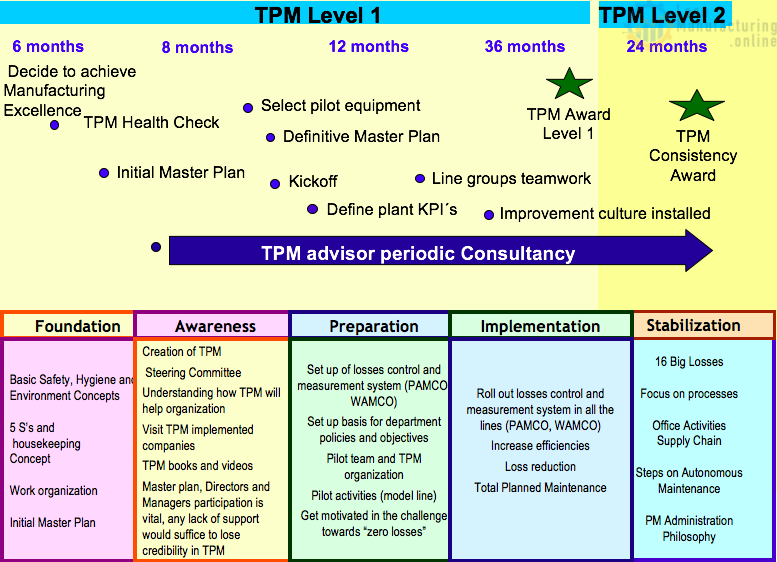

TPM Road map

TPM Master Plan