Instructor Training

Quality Maintenance. Part 1

What is Quality Maintenance? The Basic Philosophy of Quality Maintenance The 4 Ms – the Determinants of Quality Prerequisites for Promoting Quality Maintenance Developing Quality Maintenance (A 10-Step Procedure)

Read More »Chapter 5. Autonomous Maintenance. Part 2

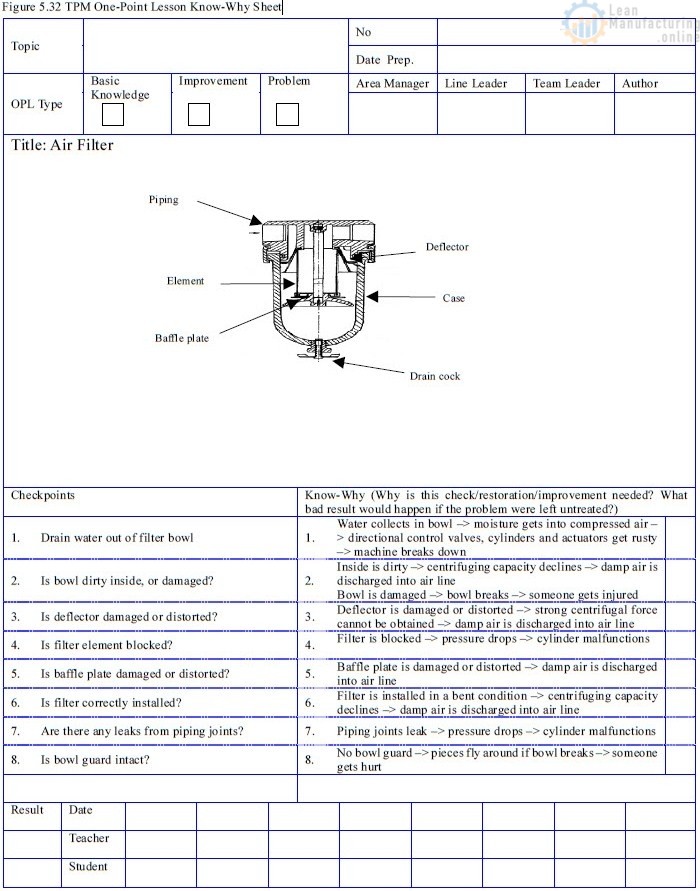

2.5 Step 4: General Inspection 2.5.1 Aims In Autonomous Maintenance Steps 1 to 3, the emphasis is on eliminating forced deterioration and sustaining basic conditions. Operators search out and eliminate equipment abnormalities, institute countermeasures against contamination sources and hard-to-access areas, and develop provisional cleaning, checking and lubricating standards. Thanks to…

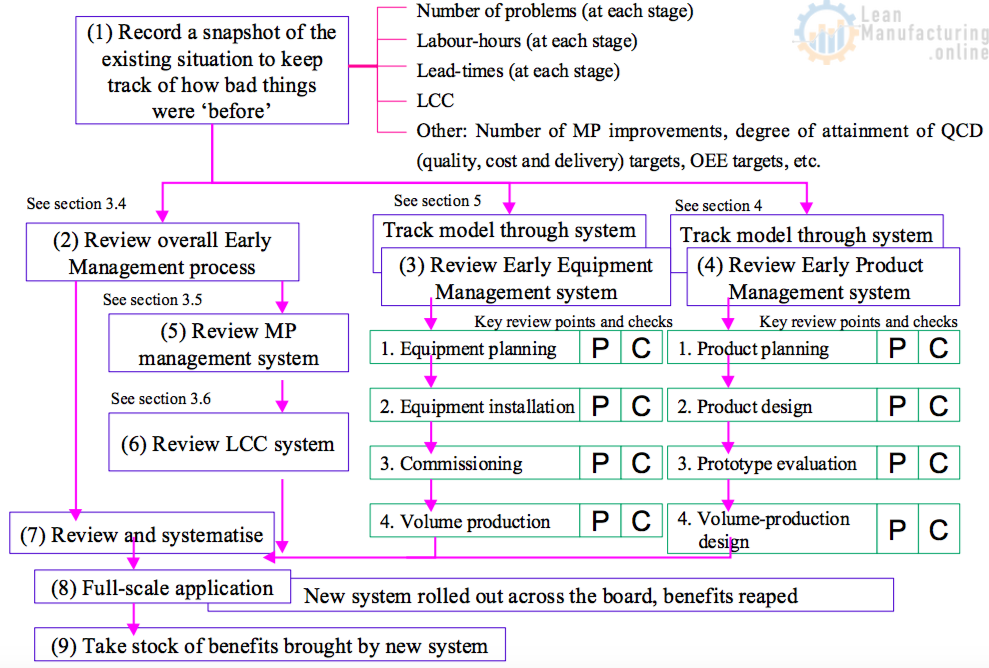

Read More »Chapter 7. Early Equipment Management. Part 1

Using concurrent engineering to reduce the time required for preparing to produce new products or use new equipment.

Read More »Losses, Costs, and Efficiency

Losses in Production System Figure “How The Losses Inherent in Production Systems (The 16 Big Losses) Are Structured” shows the structure of the losses inherent in a typical production system. These losses can be split into three main categories: those preventing equipment from being used as efficiently as it could…

Read More »