Process Excellence

Shadow boards reduce waste

Shadow boards are an effective tool for reducing waste in manufacturing and industrial settings by improving inventory management, reducing downtime, improving safety, reducing costs and promoting accountability.

Read More »Optimizing Changeover Times: A Lean Six Sigma Approach to Enhancing Food Packaging Line Efficiency

"Optimizing Changeover Times" is a Lean Six Sigma project focused on enhancing food packaging line efficiency by reducing changeover times between SKUs. Through the DMAIC framework, the project aims to minimize downtime, increase throughput, and deliver cost savings. Emphasizing data-driven decision-making and continuous improvement, this initiative seeks to set a…

Read More »World-Class Maintenance. Switching from firefighting mode to planned system

World-class maintenance is a proactive approach to equipment maintenance that emphasizes prevention, planning, and continuous improvement. It requires a shift from a reactive, firefighting mode to a planned system that anticipates and addresses maintenance needs before they become critical. This shift in mindset and approach can help organizations reduce downtime…

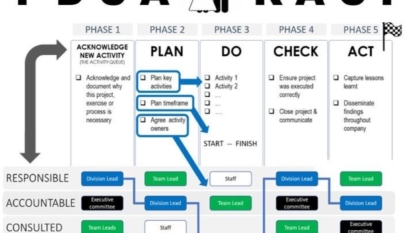

Read More »Streamlining Problem-Solving with the PDCA-RACI Framework

Combining the PDCA and RACI methodologies can create a symbiotic problem-solving methodology that emphasizes clear communication, defined roles and responsibilities, and continuous improvement. In the planning stage, the RACI framework is used to define the roles and responsibilities of team members involved in the problem-solving process. In the doing stage,…

Read More »