Process Excellence

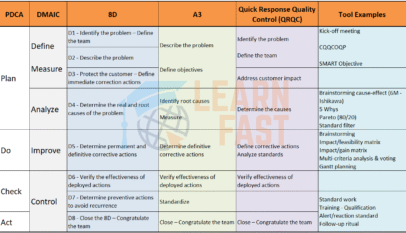

A Comparative Analysis of Popular Continuous Improvement Methodologies: PDCA, DMAIC, A3, QRQC and 8D

Explore the differences between four popular continuous improvement methodologies - PDCA, DMAIC, A3, and 8D. This blog post offers a comprehensive comparison, examining their unique steps and applications, to help you choose the most suitable approach for your organization's improvement journey.

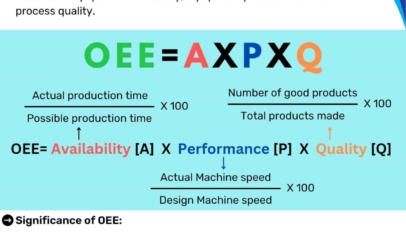

Read More »Optimizing Manufacturing Efficiency with Overall Equipment Effectiveness (OEE)

In today's competitive manufacturing landscape, maximizing efficiency is crucial for success. By embracing OEE and incorporating it into their operations, manufacturers can gain valuable insights, drive continuous improvement, and ultimately enhance their overall performance. With the right approach and dedication to improvement, companies can unlock the true potential of their…

Read More »Management View on Lean, Flow, Standard, Continuous Improvement, and Respect: A Comparative Analysis

This academic paper analyzes five management approaches: Lean, Flow, Standard, Continuous Improvement, and Respect. By examining their underlying principles, methodologies, and practical implications, the paper offers insights for managers and decision-makers seeking to optimize their organizations' performance. Integrating these approaches can create a comprehensive and balanced strategy, maximizing efficiency, adaptability,…

Read More »Planned Maintenance Case Study, Food Processing Plant

Discover how a food processing plant significantly improved its efficiency and reduced equipment breakdowns by implementing a planned maintenance approach. With a 40% reduction in breakdowns and a 20% increase in overall equipment effectiveness (OEE), this case study highlights the importance of a proactive and well-structured maintenance program for enhancing…

Read More »